Originally Published MDDI March 2006Guide to Outsourcing These potential benefits of outsourcing device design and development can help manufacturers decide whether to outsource. Robert R. Andrews

March 1, 2006

Guide to Outsourcing

The highly competitive medical device industry requires OEMs to take advantage of every possible resource, both internal and external, to stay ahead of the curve. Many device firms have capitalized on the benefits of outsourced labor and manufacturing for years. But only recently have upstream functions, such as product design and development, become a major part of the outsourcing trend. OEMs are realizing that they can capitalize on external engineering expertise to gain several advantages without jeopardizing trade secrets or intellectual property (IP). And more-effective technology transfers and training are allowing manufacturers to better internalize partnership-produced knowledge for long-term benefits.

There are many factors that must be considered to determine whether outsourcing product design and development is a strategic fit for a company. Here are 10 key benefits that medical device manufacturers may be able to realize by contracting product design and development functions.

1. Leverage Multidisciplinary Expertise

Two heads are better than one, as the adage goes. This is particularly true for product design and development. Truly innovative products rely on multiple concepts and theories for differentiation and leadership in the market. A design team with industry-spanning expertise can apply the best possible technology to the product concept. A team of engineers confined to one industry often does not have this pool of knowledge to draw from, which can make it difficult to find the best solutions to complex problems.

|

Figure 1. The sonar technology now used in sonograms was originally used in military operations. |

There are many cases of breakthrough products that were a result of ideas and technologies from unrelated disciplines. For example, when existing technology was unable to provide high-resolution internal imaging, a defense industry technology provided the solution. A technology based on military sonar mine detection was developed. This technology enabled imaging devices to resolve objects at twice the distance of then-current systems. In addition, the same sonar technology used by the navy to detect enemy submarines was applied to fetal heart monitoring (see Figure 1). Many leading medical devices have resulted from technological innovations from an unrelated industry.

2. Expand Internal Engineering Capabilities

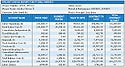

Some projects require rapid staffing scale-ups for short-term assignments, and not all OEMs are equipped to do so. Hiring full-time employees is not always economical, and adding temporary help is time-consuming and can present confidentiality risks. Outsourcing allows OEMs to leverage their partner's full-time staff to device development projects quickly and cost-effectively. Then, the proper amount of the targeted expertise can be applied at the right time. Companies can therefore avoid paying for excess labor and engineering costs. Table I shows various staffing scale-up options.

|

Table I. Various scale-up options are available to medical device manufacturers for product design and development projects. |

One medical device manufacturer was interested in developing a catheter that could be controlled remotely. Developing a console to control the catheter would require electromechanical expertise, software capabilities, a fully staffed laboratory, and testing and assembly facilities. The required electromechanical skills were outside the company's core competency. Therefore, it was more practical to quickly and temporarily outsource these capabilities, rather than developing and maintaining them in-house. The company turned to an engineering firm that could design an electromechanical console, simplifying the device, and lowering total cost.

However, it is important to note that it is difficult to make direct hourly rate comparisons of in-house design versus external engineering. Outsourced hourly rates include items that are hidden within the organization when design is conducted internally. Such internal costs include CAD workstations, software licensing fees, office and laboratory space, tools, and equipment.

3. Capitalize on Technology Forecasting

Experienced outsourcing partners should have a good grasp on up-and-coming technologies that could play a role in developing products. They should also know how these advances will affect a medical device company. Outsourcing firms have the time and resources to survey the field and look at what is coming in the future. Large engineering firms can test emerging technologies in their laboratories, which can provide an additional benefit to an outsourcing relationship.

For example, a growing aging population and rising healthcare costs have made the need to monitor patients from their homes more urgent. Advances in wireless technology for home networking have enabled the development of cost-effective devices for convenient and efficient patient home care and monitoring. Now, patients with restricted mobility can be diagnosed and monitored inexpensively in their homes by leveraging with wireless devices. Although wireless technology is relatively new to medical devices, because of its success in other industries, an outsourcing partner with expertise in this technology can help an OEM integrate it into new devices.

Should I Outsource Design? How can device manufacturers determine whether their product design and development processes will benefit from outsourced engineering? Answer true or false to the following statements. If any are true, outsourcing product design and development may be the solution. • Internal resources are stretched thin. • Medical device development projects often run over budget. • Product launches are often delayed, costing the company lost sales and additional expenses. • The company has not released a market-dominating product in several years. • The company's engineering staff's expertise is concentrated in a few core industries. • The R&D department has several new ideas, but it cannot develop cost-effective manufacturing processes to produce these concepts. • It is difficult to keep up with the competition in terms of new product development. |

4. Manage Project Timeline

Many design projects fall victim to mis- or unmanaged timelines. With internal engineering and management resources stretched thin, it is often hard for OEMs to fully commit resources to product development projects. Outsourcing partnerships can offer an advantage, because the engineering firm not only assumes project time management responsibilities, but it can also assign and manage resources. It is a good idea for both parties to agree on a program timeline up front and schedule periodic meetings for status updates. A contract with established deadlines and deliverables for each party helps to keep projects on track.

|

Figure 2. Project timeline for G.D. Searle's transdermal patch. |

G.D. Searle realized this advantage when working with an outsourcing partner to develop its transdermal nitroglycerine patch to treat patients with angina. The company's engineering partner designed the product and manufacturing process and installed it in the production facility. All the work was done within 53 weeks. A project timeline was established by the product development firm, detailing project stages from first sketch through product release, along with corresponding timeframes. Scheduled meetings and deadlines rapidly advanced the project, enabling the company to beat competitors to market (see Figure 2).

5. Control Project Costs

Similar to providing project timeline management, outsourcing partners can help device OEMs keep product development costs within budgeted goals. At contract signing, the project budget should be set and resources allocated, with written approval required for any changes. Reports should be developed and delivered on an agreed-upon periodic basis to keep all parties abreast of current expenditures versus budgeted amounts.

|

Table II. A product development cost sheet clearly categorizes incurred expenses and explicitly states contract budgets. |

Compared with internal product development, during which it can be difficult to account for time and resources, outsourcing relationships set costs for each project stage. In this way, OEMs can clearly identify the areas in which resources are invested and prevent costs from spiraling out of control. Table II shows an example of a project cost sheet.

Outsourcing design can have a positive effect on the bottom line, even if budget control is not an issue. Device manufacturers can often reduce project costs by working with external partners, because outsourcing design firms rely on past experience to optimize designs. For example, one large device company budgeted $50 million to increase the capacity of its production line. An engineering firm redesigned and retooled the company's existing equipment. The design firm was able to double production capacity for a fraction (10%) of the original budget.

6. Reduce Time to Market

External design firms can speed time to market. Engineering partners can provide end-to-end solutions, providing guidance from concept and product development through equipment design, build, and installation. Having one point of contact for all aspects of a project lends efficiency to it. Additionally, design firms can apply knowledge of similar projects and technologies thereby enhancing productivity. They can also overcome technical obstacles that can delay product introductions. External designers do not have the steep learning curves or resource limitations that internal designers often face.

|

Figure 3. The design of C.R. Bard's one-handed biopsy tool required knowledge of several disciplines. |

The design challenges posed by C.R. Bard's one-hand biopsy tool (see Figure 3) called for knowledge of several disciplines. Since a timely release was critical to the product's success, the firm turned to an outside engineering team. This third party applied expertise in medical product design, materials, and mechanism development to create a more-ergonomic product that made a biopsy procedure easier to perform. This device, operated with one hand, satisfied C.R. Bard's objectives, including a speedy market introduction.

7. Maintain Confidentiality

One of the major misconceptions about outsourcing product design and development is that it compromises corporate trade secrets. However, confidentiality can be protected through nondisclosure agreements. Companies should also insist on competitive exclusivity.

The anonymity of working with a third-party engineering firm may even provide stronger protection for a company's proprietary position than would internal development. One of the main benefits of doing so is that this option makes it difficult to track down engineers that are responsible for a design that was outsourced. Anonymity reduces the threat of a takeover by competitors and a subsequent information leak.

A confidentiality agreement can provide the OEM with a lot of power. One company worked with a partner that designed the production process for its molded hook-and-loop fasteners. Consequently, the outsourcer assigned patent rights and competitive exclusivity to the OEM. When a major medical device manufacturer approached the OEM's design firm with a project that conflicted with its partnership, the design firm declined the project because it posed a possible client conflict. But the design firm was able to connect the two OEMs, leading to a prosperous and profitable business relationship.

8. Create a Proprietary Market Position

To gain market ownership, a medical device must provide an innovative solution to an unsatisfied need. Partners that follow industry trends and keep up to date can gauge which market needs are currently unmet. Device manufacturers that specialize in one particular market segment often do not have the ability to perform those analyses. Development firms can also provide an objective analysis of a company's strengths and weaknesses to determine which needs the company can most effectively meet. Perhaps even more valuable, a good development firm can also provide guidance on how to meet those needs.

Complete and lengthy market ownership also depends on a company's products being difficult to replicate. External sources can help develop innovative products because they bring novel ideas and wide-ranging expertise to the table. But manufacturers should be wary of getting caught up in the process of making small changes to existing products and relaunching them; those types of projects and resulting products do not command price premiums.

What to Avoid when Outsourcing Engineering Partners Out of Touch with the Market. The medical device industry is highly dynamic. Partners must have medical device expertise, stay abreast of market changes, and be flexible, so that product development can be adapted as needed. Otherwise, companies risk bringing an obsolete product to market. Partners out of touch are unable to stay on top of the competition and speed a product to market. Incomplete Knowledge Transfer. It is imperative that an engineering partner provide training and support at the project's completion so that the OEM can internalize the knowledge produced during the partnership. It is important to agree to specific training guidelines at the project's onset. Communication Problems. When working with offshore partners, communication issues such as language barriers, cultural differences, and mismatched work schedules could snag product development. Evaluate potential partners' compatibility with your firm. Other countries have very different, if any, IP laws. Don't be afraid to talk to potential partners about concerns. Gratuitous Engineering. Accepting free or discounted engineering from a contract manufacturer may seem to cost less than working with an engineering firm, but it may not produce the best possible product. Contract manufacturers have an incentive to develop products to fit their manufacturing equipment instead of choosing the best design for the product, which can jeopardize profitability. A breakthrough product is worth much more than savings derived from design engineering. Discounted Engineering. With resources and product success at stake, it is unwise to choose an engineering partner strictly on price. It is important to extensively research potential partners and their qualifications before making a decision. Oversimplified Programs. Vendors that propose overly simple design plans might not fully understand the project. Moreover, simple solutions are easy to copy and could prevent growth in market share. Visit engineering partners before and during the project and evaluate their capabilities. |

Becton Dickinson and its engineering partner were able to develop a superior and convenient insulin-delivery device that earned a market-leading position (see Figure 4). This partner applied its insight on ergonomic design, injection molding, and materials to the project. The result was an innovative insulin injector pen that was easy to use and featured an audible dosage-delivery indication for visually impaired users. A low cost also helped propel the device to a market-leading position.

|

Figure 4. BD's partner used its ergonomic design, injection molding, and materials expertise to develop an insulin-delivery device. |

9. Protect Intellectual Property Rights

Device manufacturers can outsource upstream product development functions without compromising IP. To do so, they must work with partners that agree to assign IP rights after the program's completion. This means that the outsourcer either cooperates in preparing patent applications or maintains the IP as a trade secret.

|

Figure 5. In developing disposable strips, Nova Biomedical chose a partner that agreed to assign IP rights after the project was over. |

For example, Nova Biomedical needed a high-volume production capability for its innovative and proprietary disposable strips (see Figure 5). The strips are part of the submicroliter glucose monitoring system self-administered by diabetics to check blood sugar levels. They contain a miniaturized biosensor that conveys blood to an electronic reader. The company opted to have an outside engineering firm design and build customized manufacturing equipment to fit the product's unique requirements. But the company worried that involving a third party could jeopardize trade secrets. To solve the problem, Nova Biomedical chose a design firm that guaranteed the security of its IP and agreed to assign IP rights once the project was completed.

Within nine months, production units were designed, built, and installed in the manufacturing facility, and Nova Biomedical assumed ownership of them. The company now possesses the necessary capacity to meet market demand and maintain its competitive edge.

10. Keep Up with the Competition

Device manufacturers are increasingly allocating funds to outsource product design and development functions. This trend is supported by the growing budget percentages allocated to R&D. For example, in 2002, the medical industry spent 11.4% of its sales on R&D, higher than any industry except for pharmaceuticals.1 And in 2003, medical companies increased the R&D portion of their budgets by an average of 8%.2 Whether their strategy is to maintain or gain market leadership, an increasing number of medical device companies are recognizing that outsourcing product design and development is a critical strategic tool. Companies that expect to compete in the device market may find that they have to outsource.

References

1. The Medical Industry at a Glance 2004 (AdvaMed: Washington, DC, 2004).

2. “Corporate R&D Scorecard 2004,” Technology Review 107, no. 10 (2004).

Robert R. Andrews is medical division manager for the commercial group at Foster-Miller Inc. a QinetiQ company. He can be contacted at [email protected].

Copyright ©2006 Medical Device & Diagnostic Industry

About the Author(s)

You May Also Like