August 19, 2014

Chemical engineers at the Massachusetts Institute of Technology (MIT) have designed a new implantable tissue scaffold coated with bone growth factors that release slowly over time, inducing the body to rapidly form new bone that looks and behaves just like original tissue.

The new implanted tissue could change the face of treatment for bone injuries and various defects that stunt the growth of bones in the body. Currently, the preferred method of treatment normally involves transplanting bone from another part of the patient's body, a painful and invasive process that does not always supply enough bone to the intended area. Recently, Paula Hammond, engineering professor at MIT and senior author of the paper detailing the discovery of the implantable tissue, spoke about the challenges of the bone growth in an interview with MIT news.

"You want the growth factor to be released very slowly and with nanogram or microgram quantities, not milligram quantities," Hammond says. "You want to recruit these native adult stem cells we have in our bone marrow to go to the site of injury, and then generate bone around the scaffold, and you want to generate a vascular system to go with it."

|

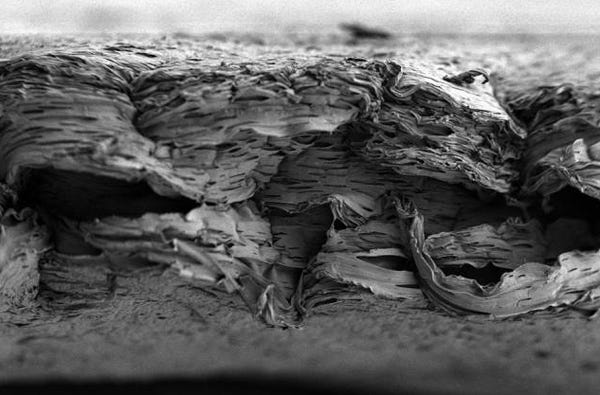

This picture from MIT researchers is a scanning electron micrograph of a porous, nanostructured poly(lactic-co-glycolic acid) (PLGA) membrane. The membrane is coated with a polyelectrolyte (PEM) multilayer coating that releases growth factors to promote bone repair. |

Of course, this process would take some time. Ideally, the growth factors from the scaffold would be released very slowly over the course of several days, or even weeks. The researchers began by testing the implantable tissue on rats with a skull defect large enough that it could not heal on its own. After the tissue was implanted, growth factors were released in combination, and these cells soon generated a layer of bone in as quickly as two weeks time. Researchers noted that the new generated layer of bone was indistinguishable from natural bone in both its appearance and mechanical properties.

"Using this combination allows us to not only have accelerated proliferation first, but also facilitates laying down some vascular tissue, which provides a route for both the stem and cells, and the precursor osteoblasts and other players to get in and do their jobs," Hammond says. "You end up with a very uniform healed system."

Along with avoiding the invasive and time consuming drawbacks of traditional bone transplant, this new implantable tissue is also biodegradable and breaks down inside the body within a few weeks. The scaffold material is made of a polymer called PLGA, and is widely used in various medical procedures and treatments. It can even be tuned to disintegrate at a specific rate, allowing researchers to design it to last only as long as it's needed.

The next step is to begin clinical testing in an effort to refine the design for more consistent use. Hammond and her team recently filed a patent for their work, and hope to soon begin testing the system on larger animals in an effort to eventually move into clinical trials.

The design could go a long way in helping patients with severe bone injuries, such as those received by soldiers in battle, individuals suffering from congenital bone defects, and patients in need of bone augmentation. Hammond and her team continue to research how their design could benefit a myriad of different bone injuries and congential defects, and with some luck, could see their design making its way into hospitals very soon.

Refresh your medical device industry knowledge at MEDevice San Diego, September 10-11, 2014. |

Kristopher Sturgis is a contributor to Qmed and MPMN.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like