November 1, 1997

Spotlight on Surface Treatment

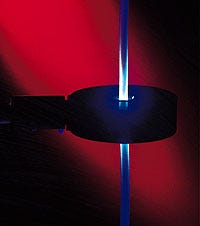

Thermal spray coatings

Pictured is a stainless-steel vibratory feeder bowl coated with a self-lubricating thermal spray coating for protection against wear and contamination. Tough, flexible Plasmadize coatings are a true composite of the latest developments in metals, ceramics, polymers, and/or dry lubricants. These materials are combined to produce a new material with an extremely low coefficient of friction and other unique properties. They create a nonporous, nonstick, corrosion-resistant surface but can also be formulated to produce a gripping or nonslip surface. General Magnaplate, 1331 Rte. 1, Linden, NJ 07036. Ph: 908/862-6200.

Surface modification

Surface modification using PhotoLink technology provides a variety of surface properties for a wide range of materials. Achievable surface characteristics include improved lubricity, hemocompatibility, infection resistance, wettability, drug delivery, tissue engineering, and functional surfaces for biomolecule immobilization. Each PhotoLink reagent can modify a product's surface with simple and environmentally sensitive processing steps. SurModics Inc., 9924 W. 74th St., Eden Prairie, MN 55344. Ph: 612/829-2700.

Electrical surface treatment

Production equipment for surface treatment of syringe hubs improves adhesion using electrical surface treatment (EST) technology. The equipment increases the surface energy of the inside surfaces of the syringe hub and greatly increases the pull strength of the needle and hub. EST technology uses electrical discharge to surface treat polymers. The treatment is done at atmospheric pressure and can be easily integrated into production lines. Tantec Inc., 630 Estes Ave., Schaumburg, IL 60193. Ph: 847/524-5506.

Diamondlike coatings

A process has been developed for depositing diamondlike coatings (DLC) on the surface of virtually any substrate capable of withstanding heat up to 200°C. This enables metals, carbides, ceramics, and even high-temperature plastics with a continuous 5-µm-thick monofilm with the properties of diamond. The substrate's surface characteristics are accurately reproduced and in most cases do not exceed the component's dimensional tolerance. The diamond film deposits uniformly on the substrate regardless of its shape or geometry. The resulting DLC is much harder than tungsten carbide and has an ultralow coefficient of friction, improved electrical conductivity, and good adhesion to the coated substrate. Surface Conversion Technologies Inc., 6160 Wellington Ct., Cumming, GA 30130. Ph: 404/889-6240.

Infection-resistant coating

An "actively sterile" infection-resistant coating for medical device components can be applied to the surfaces of metal, polymer, or ceramic devices. The deposition process, known as ion beamassisted deposition, combines metal evaporation with state-of-the-art ion beam technologies. The result is a permanent, adherent thin film that is effective against a variety of nosocomial bacteria including gram- positive and gram-negative strains as well as fecal and fungal agents. In addition to being infection resistant, the minimally leaching SPI-Argent coating provides a slick surface that prevents biodeposit and thrombosis attachment while reducing mucosal irritation. Spire Corp., One Patriots Park, Bedford, MA 01730. Ph: 617/275-6000.

Parylene coating

Custom parylene coating services are available to medical device manufacturers. Complete process engineering, precoat cleaning and masking, parylene vacuum deposition, and final inspection are all offered. The result is a thin, biocompatible, bioinert coating that resists chemicals, body fluids, electrolytes, proteins, enzymes, and lipids. Applications include esophageal and vascular stents, heart pacers, catheters, endoscopic components, circuit boards, needles, and other components. Specialty Coating Services Inc., 5707 W. Minnesota St., Indianapolis, IN 46241. Ph: 800/356-8260.

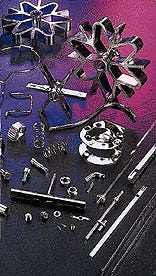

Chrome plating

Chrome plating may extend the wear life of medical devices up to 1000 times while also providing a harder, more lubricious surface. Applications include surgical and biopsy needles, tools for orthoscopic surgery, screws and pins for bones, surgical cutters, and machined parts, including cams, shafts, and pistons. A proprietary high-chromium coating that is thin, dense, hard, and nonmagnetic can be applied to all ferrous and most nonferrous metals. Electrolizing Inc., 1947 Hooper Ave., Los Angeles, CA 90036. Ph: 213/749-7876.

Lubricious coating

A specialized lubricious coating has been formulated to adhere to metallic surfaces. LubriLast-B hydrogel coats flexible wires and springs without stiffening the wire or bridging the coils. Unlike lubricants such as silicone fluid, the coating is imperceptible when dry but becomes very slippery once in contact with body fluids. This property reduces patient trauma by facilitating insertion while maximizing physician control of the device. Advanced Surface Technology Inc., 9 Linnell Cir., Billerica, MA 01821. Ph: 508/663-7652.

Gas plasma systems

Advanced gas plasma systems for surface treatment of small, molded medical parts incorporate rotating baskets that ensure that all parts receive equal exposure to the plasma, guaranteeing uniformity from part to part and batch to batch. Standard systems are offered with basket capacities of 1 and 4 cu ft. The manufacturer provides complete plasma system support, including equipment, process development, and contract treatment services. 4th State Inc., 1260 Elmer St., Belmont, CA 94002. Ph: 415/596-1600.

Thin-film surface coatings

A technological advance in thin-film surface coatings allows the low-temperature deposition of pure polytetrafluoroethylene. These molecularly bonded coatings offer controllable thickness down to submicron levels. The result is a thin-film surface coating with good adhesion, electrical, and mechanical properties. It can be applied to most materials without the need for a high-temperature cure. The coatings can be applied with no overspray or high buildup in tight dimensions. Suggested uses include release coatings, barrier coatings, friction coatings, and device coatings. Advanced Surface Engineering Inc., 5320 Enterprise St., Ste. L, Eldersburg, MD 21784. Ph: 410/552-0376.

Microwave plasma system

A low-pressure microwave plasma system provides ultrapure cleaning of metals, glass, ceramics, and optics, as well as polymer surface modification and plasma polymerization. The Model V15-G is designed for R&D and small-device production. It features a 2.45-GHz microwave frequency, an electrode-free aluminum process chamber, a mass-flow controller, microprocessor control with stored recipe capability, a graphic display for visual monitoring of process parameters, and an electronic plasma sensor. PLASMAtech Inc., 1830 Airport Exchange Blvd., Ste. 120, Erlanger, KY 41018. Ph: 606/647-0730.

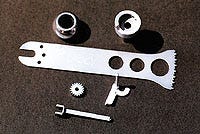

Electropolishing

Electropolishing is a stress-free electrochemical process that, by removing surface impurities in metal, improves the fatigue life of springs, stampings, and other manufactured parts. The process removes the high points on stainless steel and redeposits a clear, chemically bonded oxide layer. This layer retards corrosion and resists impregnation by bacteria. The absence of scratches, strains, metal debris, and embedded abrasives characterizes the electropolished surface. New England Electropolishing Company, Inc., P.O. Box 845, Fall River, MA 02722. Ph: 800/672-6616.

Hydrophilic coatings

Catheter-associated infections are a leading cause of hospital-acquired illnesses. According to the results of a company's in vitro study, its Medi-Coat hydrophilic coatings, which contain silver compounds, may significantly reduce such catheter-related infections. Greater aqueous diffusion in the hydrogel coatings produces a greater silver ion concentration at and just above the device surface. Antimicrobial agents are entrapped in the coatings, and the hydrophilic property of the coating allows drug molecules to dissolve in water and diffuse out of the polymer matrix. This provides an antimicrobial environment near the surface of the catheter, preventing adhesion and propagation of bacteria. STS Biopolymers, 336 Summit Point Dr., Henrietta, NY 14467. Ph: 716/321-1130.

Diamond coating

A wear-resistant amorphous carbon coating offers corrosion resistance, hardness approaching that of natural diamond, and good adherence to stainless steel, titanium, and Co-Cr alloys. TetraBond, which is primarily sp3-bonded carbon, has good biocompatibility and a pleasing black color. The manufacturer's performance tests show that it reduces cutting forces and temperature on sharp-edged drills, burrs, and blades while extending instrument life. The coating is also being evaluated for use on orthopedic and cardiovascular implants. Multi-Arc Inc., 200 Roundhill Dr., Rockaway, NJ 07866. Ph: 973/625-3400.

Metal surfacing

A company offers complete metal-finishing services including polishing, graining, blasting, and anodizing for both aluminum and titanium products. Marking capabilities include laser, silk screen, and deep imaging techniques. With its Steri-Color method, the company recently completed a qualification process for fade-resistant-color aluminum anodizing that is compatible with Sterrad sterilization methodology. The company also has an electropolishing facility for stainless steel. Danco Metal Surfacing, 44 La Porte St., Arcadia, CA 91006. Ph: 818/445-3303.

Gas plasma treatment

Gas plasma technology is used to modify a variety of materials and surfaces. The process can achieve several results: transform surfaces to be hydrophobic, hydrophilic, or lubricious; increase bond strength; improve wettability; ultraclean; etch; and deposit coatings. A few of the products currently treated with the gas plasma are catheters, guidewires, intraocular lenses, syringe hubs, sensors, and filters. The process is environmentally sensitive, yields uniform results, and is reproducible. Advanced Plasma Systems Inc., 12000 28th St. N., St. Petersburg, FL 33716. Ph: 813/573-4567.

Titanium nitride coating

Titanium nitride (TiN) coating is a molecular bond of TiN to properly prepared metal surfaces. It provides surface hardness and lubricity to reduce friction and improve wear. TiN is FDA compliant and gold colored, and it provides an extremely hard surface (85 Rc) at 0.0001 in. thick. Galling of mating stainless-steel components is eliminated. The coating can be repeatedly autoclaved or otherwise sterilized, and it provides wear resistance, corrosion resistance, improved release from tissue, and less glare than uncoated instruments. BryCoat Inc., 976 4th St. N., Safety Harbor, FL 34695. Ph: 800/989-8788.

You May Also Like