April 27, 2011

|

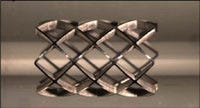

This preliminary stent was machined using |

Two heads are better than one, according to the old saying. But in the case of the Nitinol Commercialization Accelerator (NCA), no less than six institutes and organizations are putting their heads together to develop nitinol products for a range of applications, including in the medical device and aerospace fields.

See Main Article: From Rust to Riches: Medical Device Manufacturing in Ohio's Northeast |

Although it was discovered in the 1960s, nitinol began to take off in the 1990s when designers and manufacturers realized that its unique shape-memory and superelastic properties, biocompatibility, flexibility, and kink-resistance could benefit a host of medical device applications. Since then, the alloy has contributed to the development of self-expanding stents and improved devices ranging from guidewires to needles. Among the material's drawbacks, however, is that it's difficult to process. That's where the NCA comes in.

Supported by an investment from the Ohio Third Frontier Wright Centers of Innovation (Columbus), the accelerator represents a collaborative effort by the Cleveland Clinic's Lerner Research Institute (Medical Device Solutions), Norman Noble Inc. (Highland Heights, OH), the University of Toledo, the department of materials science and engineering at Case Western Reserve University (Cleveland) and the metallic materials section at the NASA Glenn Research Center (Cleveland). The NCA's objective is to develop a comprehensive and focused approach to nitinol design, bringing new alloys and products to market within the next few years.

|

John Lewandowski |

"The NCA is a unique joint venture combining university, government, and industry participation," remarks John Lewandowski, Leonard Case Jr. professor of engineering at Case Western Reserve and director of the university's Center for Mechanical Characterization of Materials. "Its objectives include purchasing equipment for nitinol prototyping, commercializing nitinol devices, and establishing Ohio as a center of excellence. The plans are also to create graduate courses that cover shape-memory alloys and begin a cooperative program to train and retain Ohio college graduates." With that mission in mind, the NCA hopes to train a future workforce of researchers and students in nitinol properties and production methods. In addition, it plans to test a variety of nitinol alloys for potential use in new products to be developed in Northeast Ohio.

Broad and comprehensive, the NCA's areas of expertise include medical devices, particularly cardiovascular and orthopedic devices; nitinol alloy development and transition-temperature control; nitinol device manufacturing; nitinol actuators; materials processing; fatigue testing; and materials analysis. "Certain nitinol products are subjected to cyclic loading, and the fatigue properties are of particular interest," according to Lewandowski. "Thus, the team will be investigating various concepts related to processing and manufacturing that will improve the alloy's fatigue behavior."

The accelerator was originally awarded a $3 million grant in 2009 by the Ohio Third Frontier Commission for the purchase of capital equipment to be installed at facilities at the Case School of Engineering, the Cleveland Clinic, and the University of Toledo. Since then, matching funds have increased overall investment in the project to $10 million, $1.2 million of which are earmarked for use by Case Western Reserve's department of materials science and engineering.

"We will be purchasing and housing equipment for processing, thermal characterization, and mechanical characterization of various forms of nitinol of interest to our collaborators," Lewandowski says. "As for the Cleveland Clinic, it will be installing a femtosecond precision laser to enable advanced manufacturing of nitinol medical devices with high precision, low distortion, and excellent surface characteristics." Nanosecond and picosecond lasers impart significant heat to the medical device, Lewandowski notes. Heat, in turn, leads to the creation of slag and the formation of a recast layer that must be removed using hazardous chemicals. Femtosecond lasers reduce this problem substantially by utilizing an ultrashort pulse that creates much less surface damage.

Initial equipment subcontracts were completed in January and February, and the purchase of machinery has begun. "Preliminary machining experiments using the femtosecond laser are under way, as are designs and prototypes of various medical devices," Lewandowski comments. "Fatigue testing of various nitinol compositions, sizes, and shapes has also been completed. Presentations and publications on the results obtained from these tests are imminent.

The NCA team has big plans for all that equipment. In addition to basic research, it is developing several potential commercial nitinol products, such as a nitinol pacemaker clip, an ablation stent, and an expandable intervertebral cage for spinal fusion. It is also working on an endovascular repair system for use in the types of cardiovascular surgeries performed by Eric Roselli, a staff surgeon in the Cleveland Clinic department of thoracic and cardiovascular surgery and a member of the teaching faculty at the Cleveland Clinic Lerner College of Medicine. In addition, the group is developing a variety of other nitinol-based medical devices and components, including a minimally invasive blood clot-removal device, pedicle screws, an ankle orthosis for addressing drop foot, and an organ positioner. Looking toward eventual commercialization, team members have filed several patents or patent disclosures in the medical device and aerospace areas, Lewandowski says.

Above and beyond conducting its activities in the rarified atmosphere of university laboratories and hospital research facilities, the NCA is also dedicated to working with local manufacturers to further nitinol's fortunes. One such company is NCA member Norman Noble, which is establishing a cooperative program for training Ohio college graduates. As part of this effort, other NCA members are creating summer jobs for interns and organizing graduate-level projects to provide students with access to the accelerator's expertise and equipment.

"The Northeast Ohio area is a hub for advanced materials, medical technologies, and advanced manufacturing," Lewandowski concludes. "We are interested in continuing our collaboration with others in order to further develop materials such as nitinol and advance the manufacturing processes required for converting these materials into medical device and aerospace products."

|

|

About the Author(s)

You May Also Like