December 19, 2012

|

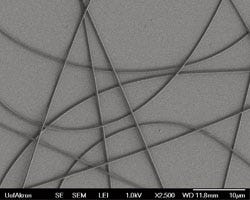

SEM image shows peptide-functionalized poly-benzyl L-glutamate nanofibers produced using a new polymer initiating system that can work with an array of drugs, biologics, vitamins, and other therapeutics. |

Medical device manufacturers have traditionally fabricated drug-delivery and other combination products using different polymeric systems for different therapeutic agents. In addition, they have had to add the agents to the polymer ingredients before producing the polymer structure, causing potential processing issues. Now, researchers in the College of Polymer Science and Polymer Engineering at the University of Akron (Ohio) have simplified the process of producing combination products, developing a single, multifunction polymer system that can incorporate a vast array of drugs, biologics, vitamins, and other therapeutics.

"The innovation in our technology is that we have been able to come up with an initiating system for ring-opening polymerization, a process used for creating all polylactic acids and biodegradable polyesters used in biomaterial applications," remarks Matthew Becker, associated professor of polymer science at the University of Akron. Constructed of a highly strained, triple-bond molecule called dibenzylcyclooctyne, the initiating technology is compatible with a range of biodegradable polymeric systems, including cyclic lactic acids, caprolactones, and amino acid-based benzyl-protected L-glutamic acid, which is often conjugated with paclitaxel to treat cancer.

While it is able to work across polymers, the new initiating system also survives the electrospinning fiber-generation process, a fabrication method that typically uses very small amperage but very high voltage. "A polymer as energetic or strained as ours would not normally survive a fabrication process like this," Becker explains. "But our technology enables us to form such constructs as nanofiber mats and then functionalize them with bioactive species after the polymer construct is made."

Most combination products, according to Becker, are typically the result of a process in which the peptide, carbohydrate, drug, or prodrug is put onto the polymer before it is fabricated into a structure. But because most polymerization processes require heat, solvents, or other processing steps that can damage the therapeutic agent, manufacturers must carefully derivatize, characterize, and control the process. "Here, in contrast, we can fabricate the polymer construct using the electrospinning process, and our strained reactive groups survive this process," Becker comments. "This means that after our construct is fabricated, we can go back and put the peptide, carbohydrate, or DNA molecule on last, which makes our process much more cost effective and much more likely that the bioactive species, which is the most expensive part of the entire construct, is going to be preserved."

In addition to developing its polymer technology to produce such medical devices as wound-care bandages, the Akron team is also in the early stages of using the material to create blood vessels. "While researchers have had real clinical success in using electrospun nanofibers to fabricate tubes in very precise ways as surrogates for blood vessels, incorporating peptides and gross factors to enhance or accelerate blood-vessel formation remains one of the grand challenges facing regenerative medicine," Becker explains. "However, our new polymer system can be combined with bioactive species to accelerate this process."

Because the researchers are working with polymers and functional groups that are already employed in biomedical applications today, incorporating them into existing applications using the new technology should be a relatively seamless process, Becker remarks. "We are still going to have to perform due diligence, but despite the very rigorous review process, we think that our technology is a much more translationally relevant strategy than other strategies that have been brought forward recently."

About the Author(s)

You May Also Like