The German startup that developed 3D-printed breast-reconstruction scaffolds made from a resorbable polymer is partnering with Fraunhofer to design next-generation scaffolds for other parts of the body.

July 1, 2021

BellaSeno GmbH, a startup that has developed 3D-printed breast-reconstruction scaffolds made from a resorbable polymer, has begun a program to design and evaluate next-generation scaffolds for tendon and ligament reconstruction. The initiative is funded by the German state of Saxony and run in collaboration with the Fraunhofer Institute for Cell Therapy and Immunology (Fraunhofer IZI).

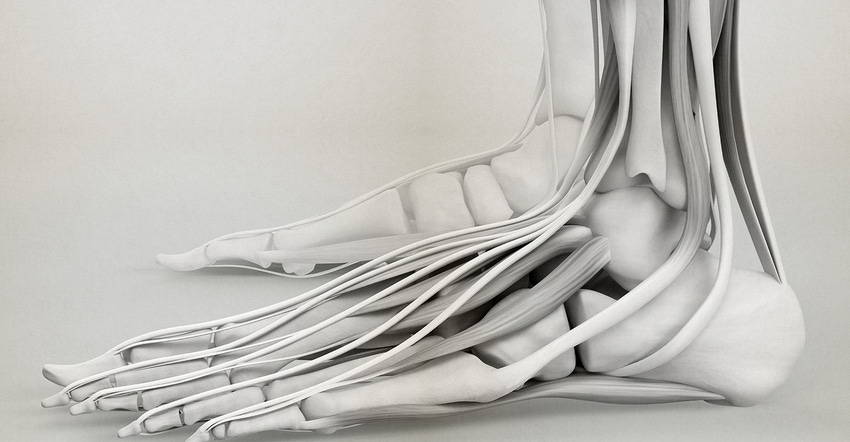

Based on BellaSeno´s proprietary Senella platform, the scaffolds are made of polycaprolactone (PCL), a biocompatible and resorbable polymer that is FDA-approved and CE-marked for a variety of clinical applications, said BellaSeno in the announcement. The scaffolds are designed for gradual resorption by the body while the patient's tissue regenerates, resulting in natural tissue with no foreign artifacts. The technology has already generated promising results in first-in-human trials in breast reconstruction, said BellaSeno. Fraunhofer IZI will be responsible for the development of an animal model for subsequent in vivo testing of the scaffolds for tendon and ligament applications.

Torn tendons and ligaments currently are treated with conservative condition management techniques, surgical intervention, or replacement with autografts. The global orthopedic soft tissue implant market is projected to reach $9.4 billion by 2024, according to a report from Grandview Research.

"We believe that our Senella technology is very well suited to address the growing need of tendon and ligament reconstruction," said Dr. Navid Khani, Head of R&D at BellaSeno. “Due to its porous and flexible structures, Senella scaffolds are ideal for seamlessly fitting into the bone and muscle environment. As a first step, we will develop novel porous architectures that can bear the mechanical forces typical for tendon and ligaments.”

"We are delighted about the [state] funding and the further expansion of our good collaboration with Fraunhofer IZI. Most importantly, this program allows us to enter new high growth markets with our Senella resorbable implant technology," said Mohit Chhaya, PhD, CEO of BellaSeno. The company’s vision is to create a family of scaffolds that can target tendons and ligaments in shoulders, hands, Achilles tendons, and other parts of the body, added Chhaya.

Leipzig-based BellaSeno was founded in 2015 and received ISO 13485 certification for its 3D-printed bioresorbable implant technology in July 2019, as reported in PlasticsToday. In November 2019, it signed an agreement with materials supplier Evonik for the long-term use of its Resomer bioresorbable polymer.

About the Author(s)

You May Also Like