August 29, 2013

The current medical device industry trend towards reduced manufacturing costs has catalyzed new business opportunities for innovative suppliers. Equipment using technologies designed to replace expensive manufacturing processes is generating new interest, as latest statistics reveal.

In the catheter manufacturing sector, more targeted, cost cutting solutions are replacing older overly engineered technologies. Hot air tip forming is one such alternative gaining traction in today's competitive business environment. Beahm Designs, a supplier of catheter manufacturing equipment, has developed a leading edge solution to address this emerging trend. Beahm Designs Auto-Tipper 510-A was designed as an easy-to-operate, low-cost alternative to RF tipping that works with both glass and metallic dies.

As with any new process, hot-air thermal tipping brings up some common questions among end users. Here, Beahm Designs CEO Anita Beahm addresses some of the most frequently asked questions received during presentations and workshops.

|

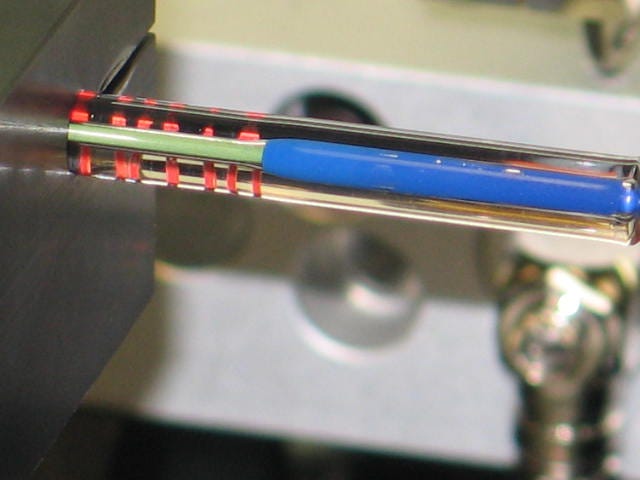

The above image shows glass-mold tip forming. The use of glass allows the user to see the materials forming within the mold and provides visibility for process control. |

Five Commonly Asked Questions about Hot Air Tipping

Question 1: What ranges of temperature will the Hot Air Technology accommodate and what is the average cycle time?

Both the 510-A, and the two-up system, 512-A system accommodates temperatures ranging between 250° F-650°F. The average cycle time is 20 seconds.

Question 2: How do you address "flash" or material that leaks from the mold?

This is the greatest tipping challenge. With metallic dies the mandrel can be integrated or welded to the die with glass a tapered mandrel can be used to seal the gaps but each of these methods has it's own challenges.

Question 3: What types of mold releases are available?

70/30 IPA/Water works for most materials and does not have biocompatibility issues. Otherwise pure silicone or a silicone based solution can be used but is difficult to clean from the finished product.

Question 4: What types of materials does the 510-A accommodate?

Virtually all thermoplastics but not all thermo-formable materials can be formed into any geometry.

Question 5: How can I determine whether hot air tipping is a viable alternative to my current process?

Companies like Beahm Designs will sign your NDA, then using your supplied materials, run trials in our applications lab. At Beahm Designs, we identify and document parameter settings, cycle time and photograph the session for review and testing, and guarantee results.

Hot Air Tip Forming Video Demonstration:

Anita Beahm is available to answer questions on the hot-air tipping via email.

About the Author(s)

You May Also Like