March 27, 2015

Because the wires used in neurostimulation and other implantable devices are minuscule and fragile, extruding an insulation layer around them is no easy feat

Steve Maxson

|

A polymer jacket is extruded around the fine wires used in such implantable medical devices as neurostimulators, cochlear implants, and guidewires. |

Among the most difficult and exacting medical device tubing applications is the extrusion of fine-wire jacketing. Although a highly specialized niche process, jacketing fine wires with polymer-based materials is crucial for manufacturing miniaturized medical devices.

Insulating Fine Wires

In several medical device applications, polymer material is jacketed over fine wires in order to insulate them. For example, in neurostimulation devices used for electrically stimulating the spinal cord, brain, or bladder to treat chronic pain, thin lead wires are jacketed to protect the body from undirected electrical pulses. Similarly, in cochlear implants, polymer material is used to insulate the wires between the implant body and the electrode contact. In both types of devices, very fine lead wires are jacketed using an ultrafine layer of such fluoropolymers as ETFE, FEP, PFA, and PTFE.

However, extruding a polymer layer around a wire core is easier said than done. Made from titanium, 300-series stainless steel, silver-plated copper, platinum composites, or such super alloys as MP35N, the solid wires used in neurostimulation and cochlear implant applications typically range in diameter from 0.0015 to 0.008 in. (0.038 to 0.203 mm). Depending on the diameter of the wire, the jacket's minimum wall thickness can measure as low as 0.0005 in. (0.013 mm)--smaller than the diameter of a human hair. A common wire used in neurostimulation devices and cochlear implants is made from titanium alloy, has an outer diameter of 0.004 in. (0.102 mm), and is jacketed by an ultrathin fluoropolymer layer with a thickness up to 0.001 in. (0.025 mm). Such wires are so small that they are difficult to see with the naked eye.

|

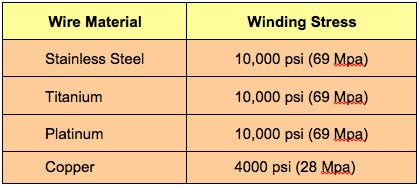

A metal's winding stress determines how much tension a wire can undergo during the dereeling and winding process. |

In addition to overcoming the daunting size challenges associated with manufacturing tiny jacketed wires, the tension requirements for introducing (dereeling) and winding fragile ultrafine wires is a delicate process. If too much tension is applied, the wires can deform or break. The appropriate tension level for the extrusion process in question can be determined by the wire's gauge and yield stress. Table I provides a general guide for determining the winding stress of different fine-wire materials.

Based on its winding stress and cross-sectional area, a 0.004-in.-diam titanium wire has a dereeling and winding tension level of approximately 56 g. In contrast, a 0.004-in.-diam copper wire has a tension level of approximately 23 g, just slightly higher than the tension level of 20 regular-sized paperclips.

These tension levels result from the fine-wire wrapping around a lightweight sheave but not from the sheave itself. However, the weight of the sheave can also impact tension levels. For example, an extremely light sheave can easily add 4 to 10 g of tension. Because of the challenges associated with dereeling and winding ultrafine wires, special decoiling and winding equipment is required for controlling tension levels down to 20 g.

Besides size and tension constraints, jacketing fine wires requires the use of specialized microextrusion equipment that can produce low output rates without degrading the polymer. Exposing the polymer to excessive residence times in the barrel and screw channels can result in material degradation. To prevent this issue, manufacturers must occasionally resort to the use of a bleed port, which allows for significantly lower outputs than a microextruder.

Once a wire has been jacketed, manufacturers perform inline measurements to extract quality data. However, performing quality control is challenging because it is difficult to measure the wall thickness of the jacketed layer down to 0.001 in. using ultrasonic wall measurement technology. Consequently, manufacturers typically measure the core wire before the extruded jacket is applied and then measure the final outer diameter after extrusion in order to calculate the wall thickness of the jacket.

Jacketing Guidewire Core Materials

The miniature nitinol and stainless-steel core wires used in guidewire constructions feature outer dimensions down to 0.015 in. (0.37 mm). In some applications, a radiopaque polyurethane or Pebax polymer with wall thicknesses down 0.0015 in. (0.038 mm) is extruded over the core wire. However, since polyurethane is a tacky polymer, core wires with polyurethane jackets include a hydrophilic coating to reduce the coefficient of friction. While some of these wires are straight, others feature a flexible, centerless-ground distal tapered tip that allows the wire to travel more easily through the tortuous vessels of the body.

Extruding a polymer jacket over a continuous, straight core wire is fairly uncomplicated. But extruding a jacket with a uniform wall thickness continuously over discrete lengths of core wires is problematic because the wires must be individually fed into the extrusion equipment. While it is possible in some cases to maintain a jacket with a consistent outer diameter over the entire length of the core wire, it is challenging nonetheless because the wall thickness transitions quickly from the proximal shaft to the ground distal end.

Steve Maxson is technical sales manager at Raumedic Inc. (Leesburg, VA). Reach him at [email protected].

For more blogs on tubing and extrusion, try out |

About the Author(s)

You May Also Like