February 14, 2014

Nanomaterial advances are set to greatly increase the performance of orthopedic implants, if a recent presentation at MD&M West in Anaheim, CA is any indication.

Peoria, AZ-based Nasseo last fall won FDA clearance for its TiArray Dental Implant System that uses a special titanium dioxide nanotube surface to make its titanium screws more bone growth-friendly, hopefully creating a bond between the implant and bone quickly enough to prevent inflammation from developing.

The nanotube surface is all about "essentially mimicking porous bone at the nano and molecular scale," Nasseo's co-founder and chief operating officer Kayvon Pourmirzaie explained during a Learning Lab on Tuesday at MD&M West.

"You want to see all these cascading impacts that occur for bone remodeling. ... Reducing inflammation is key," Pourmirzaie says.

|

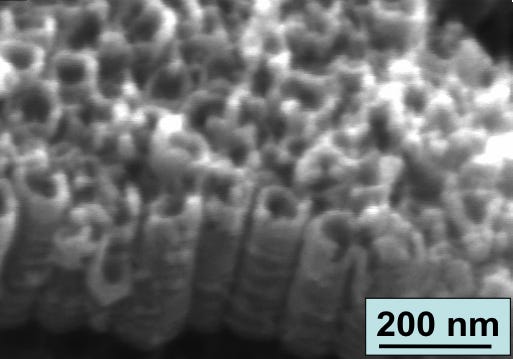

Micrographs from Nasseo show structures of the vertically aligned TiO2 nanotubes on titanium substrate. |

The surface technology is licensed from the University of California, San Diego, where researchers led by material sciences professor Sungho Jin, PhD, spent more than eight years fine-tuning a secret sauce of chemical processes, anodizing and heating that altered the 5 nm titanium dioxide surface already naturally present on CP4 titanium.

"What you end up with are 300 nm nanotubes that are patterned and uniform across the surface," Pourmirzaie says. (Nasseo CEO Garrett Cale Smith, PhD, was a co-inventor.)

Trials are starting at the Arizona School of Dentistry and Oral Health.

Orthopedics device makers for years have been making metal materials porous down to levels of a millionth of a meter. Pourmirzaie's talk, for example, was preceded by a presentation by Wright Medical Technology's applied research directory Jon Moseley, PhD, who described the company's Biofoam titanium "foam" meant to compete with the more expensive Trabecular Metal Material, a tantalum foam produced by Zimmer.

The technology Nasseo is using, however, is creating a porous surface billionth of a meter levels. Pourmirzaie sees a wide variety of opportunities--including enhancing the porous metals already out there and potentially coating plastic orthopedic parts, such as PEEK modulus for spinal implants, to make them more bone friendly.

It is also more soft tissue friendly. Biologics and drug delivery might also be enhanced with the nanotubes surface.

Moseley mused to Pourmirzaie that the nanotube tech could be used to make prosthetics friendlier in skin interfaces.

"I think the possibilities really are endless," Pourmirzaie says.

Chris Newmarker is senior editor of MPMN and Qmed. Follow him on Twitter at @newmarker.

About the Author(s)

You May Also Like