March 12, 2014

|

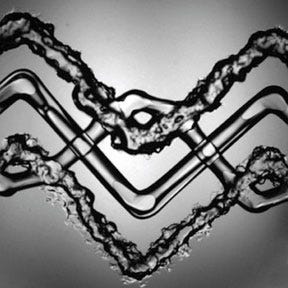

Vascularized tissue constructs in a layered zig-zag pattern 3-D printed by Harvard researchers. (Courtesy Kolesky et al./Wyss Institute, Harvard) |

Harvard researchers appear to have overcome a significant stumbling block when it comes to 3-D printing living tissues and organs. They've demonstrated a method for creating tissues interlaced with the blood vessels needed to deliver nourishment to them inside a human body.

Led by Jennifer Lewis, PhD, the researchers used a custom four-head 3-D printer and a novel ink to create a patch of tissue composed of skin cells and an extracellular matrix material that was interwoven with blood-vessel-like tubular structures.

"This is the foundational step toward creating 3D living tissue," said Lewis in a press release from the Wyss Institute for Biologically Inspired Engineering at Harvard University (Boston) announcing the achievement. Lewis, graduate student lead author David Kolesky, and the team reported their results in "3D bioprinting of vascularized, heterogeneous cell-laden tissue constructs" in the February 18 issue of the journal Advanced Materials.

The team began with two bio-inks, one carrying a gelatin-based extracellular matrix and the other composed of the extracellular matrix plus either mouse or human skin cells. The crucial third ink was truly novel - it actually thins, becoming more liquid, as it cools. This ink was used to print the vascular structure.

3-D printing accomplished, the researchers chilled their patch of printed tissue and suctioned out the now-liquid third ink. This left behind the tissue construct riddled with a network of hollow tubes.

Their final step was the injection of human endothelial cells into the vascular network. Those cells then grew into blood vessel linings.

In an article for the MIT Technology Review, Lewis told author Susan Young that the smallest channels the researchers printed were about 75 µm in diameter. This is much larger than the tiny capillaries that exchange nutrients and waste throughout the body, she said. The hope is that the 3-D printing method will set the overall architecture of blood vessels within artificial tissue and then smaller blood vessels will develop along with the rest of the tissue. "We view this as a method to print the larger vessels; then we want to harness biology to do the rest of the work," said Lewis.

"Tissue engineers have been waiting for a method like this," Don Ingber, MD, PhD, Wyss Institute founding director, said in the Harvard press release. "The ability to form functional vascular networks in 3D tissues before they are implanted not only enables thicker tissues to be formed, it also raises the possibility of surgically connecting these networks to the natural vasculature to promote immediate perfusion of the implanted tissue, which should greatly increase their engraftment and survival.".

The 3-D printing of living tissues, while not yet exactly commonplace, is on the threshold of commercial availability. Last month, we reported that Organovo Holdings Inc. (San Diego, CA) has delivered the first samples of its 3-D printed liver tissue that is to be sold to drug companies for the toxicity testing of potential new drug candidates.

Harvard's Lewis has been busy of late when it comes to 3-D printing breakthroughs in medtech. A research group she led announced last year that it had figured out how to 3-D print miniature batteries that could potentially be used with medical devices.

Stephen Levy is a contributor to Qmed and MPMN.

About the Author(s)

You May Also Like