On average, an organization’s lowest-performing technician cost 86% more than the top-performing technicians, a medical device benchmark report shows.

April 5, 2023

Unlike other industries, which saw field service demand drop during the height of the COVID-19 pandemic, medical device field service organizations managed to maintain pre-pandemic service levels – or saw an increased demand – according to Aquant, a software company spearheading AI and data integration within the field service industry.

That’s not to say that medical device field service organizations have had it easy. The New York, NY-based firm notes that more-tenured technicians retired faster than their replacements could enter the workforce, even with the uptick in hiring. As a result, the sector is seeing a wider skills gap than ever before.

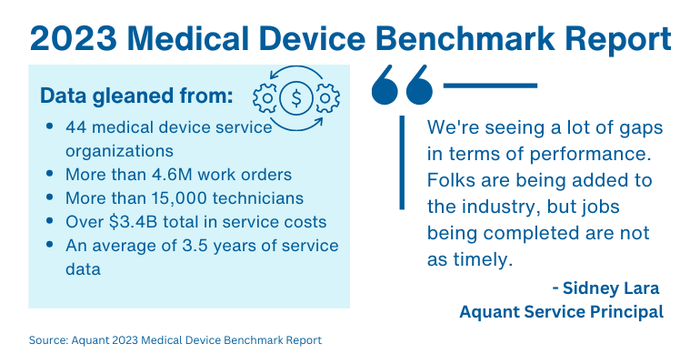

Aquant recently gathered and analyzed anonymized service data from leading medical device field service companies to publish the 2023 Medical Device Benchmark Report. The data was analyzed using Aquant’s Service Intelligence Platform, which includes Service Language Processing (SLP), a unique engine designed to read service language and identify observations, symptoms, and solutions described in free text.

The report measures data from before an organization deployed Aquant’s artificial intelligence solution. With this technology, Aquant digs into data ranging from customer relationship management and parts inventory to service tickets, handwritten records, etc. The company says its method of SLP allows Aquant to draw out patterns and recommendations based on raw data.

“We can use data to understand where we should focus or maybe streamline the traditional training,” Sidney Lara, Aquant’s service principal, told MD+DI.

You’ve heard of design for manufacturability, but what about design for serviceability?

“You see a lot of organizations wanting to understand, ‘how do we take this serviceability, this tremendous gold pot of information, and design our products to improve serviceability or to reduce service incidents.”

The data shows that certain medical device products have common failure modes, Lara said.

“So, how do we take that information and design it into our product? I think that’s a big trend we see amongst organizations [is a] willingness to want to do better,” he said.

Your workforce skills gap is costing you money

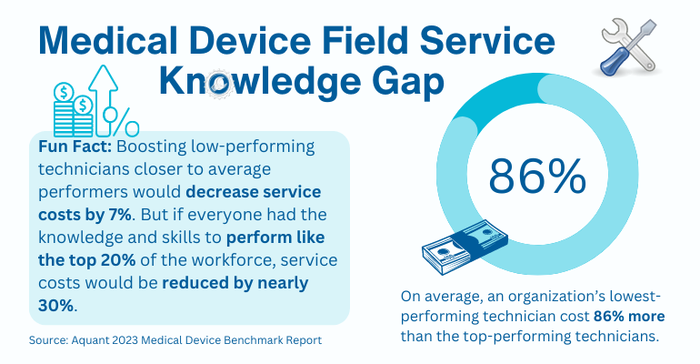

The skills gap, also known as the knowledge gap, is expensive. On average, a medical device field service organization’s lowest-performing employees cost 86% more than the top-performing employees, according to Aquant’s report.

“Significant knowledge gaps result in uneven technician performance, inevitably impacting the customer experience,” the report authors note. “When teams are equally-knowledgeable about equipment and service best practices, as well as conscious of customer preferences, the service experience becomes a memorable one.”

According to the report, boosting low-performing technicians closer to average performers would decrease service costs by 7%. But if everyone had the knowledge and skills to perform like the top 20% of the workforce, service costs would be reduced by nearly 30%.

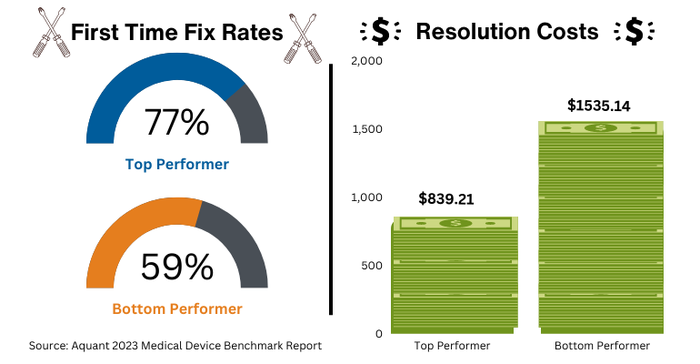

In the case of first-time fix rates, Aquant’s report shows a gap between “heroes” (top performers within an organization) and “challengers” (bottom performers within an organization) of nearly 18%. But, when measured against resolution cost, the report suggests that this moderate gap can lead to skyrocketing costs, with almost a 59% difference in costs between “heroes” and “challengers” at an organization.

Relying on FTFR alone creates blind spots for service leaders, according to the report.

“When FTFR is measured in isolation, organizations struggle to measure the true impact

of the workforce skills gap—mainly because they can’t visualize how this KPI drives up service costs and negatively impacts customer satisfaction,” the report authors note.

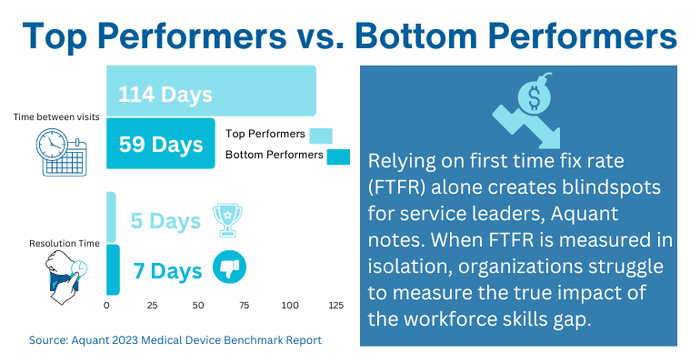

Higher-performing medical device field service organizations have a better distribution of knowledge among employees, according to the Aquant report. For example, at top-performing companies the difference between “heroes” and “challengers” in terms of average time between service visits is just 35%, compared to a 60% difference between a low-performing company’s “heroes” and “challengers.”

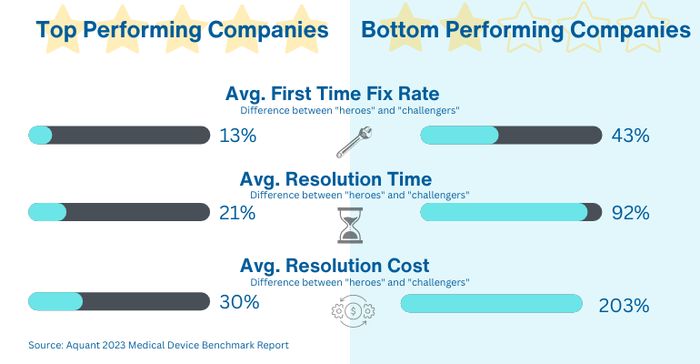

Looking at average FTFR, the difference between “heroes” and “challengers” at top-performing companies is 13% while the FTFR gap at low-performing companies is 43%.

At top-performing companies, the difference between “heroes” and “challengers” is 21% for average resolution time while the same gap at low-performing companies is 72%.

And finally, the difference between “heroes” and “challengers” when it comes to resolution cost is a whooping 203% at low-performing companies versus 30% at top-performing companies.

Efficiency matters in medical device field service

Lara said the biggest opportunity he sees, not just in medical devices but in the broader field service industry, is improvements in efficiency. Aquant analyzed efficiency-related metrics, such as FTFR, and the report notes that top medical device service companies made more accurate fixes on the first try, resulting in a more than 4.5% increase in FTFR.

These top-rated medical device field service companies also provided more remote and simple fix-it-yourself options, leading to a 34% increase in time between visits, according to the Aquant report.

“While [FTFR] is a KPI or metric that is broadly used, what we see from the data is it's never really taken to the next level,” Lara said.

The firm notes that using AI and predictive technology models can help companies glean insights and make critical business decisions quickly, which can help improve those critical metrics like FTFR and minimize downtime.

“The fact that we have the ability to get ahold of all this information, we find it a major benefit in partnering with our customers to provide these insights,” Lara said. “We're semitransparent meaning that we'll give you an aggregate view of how you look against the competition without unveiling who that is.”

Aquant’s 2023 Medical Device Benchmark Report also highlights ways that thriving organizations are combating high service costs, increased time to competency, and other service delivery hurdles.

For example, top companies are putting their trust in data rather than hunches and intuition. Assembling a workforce with a diverse mix of soft and hard skills is another way successful companies are creating a better customer experience, according to Aquant. Investing in relevant tools and training, such as AI, also makes a difference, particularly for the younger workforce generations. Other recommendations from the report include shifting to proactive service models and leveraging shared knowledge.

About the Author(s)

You May Also Like