3D Printing

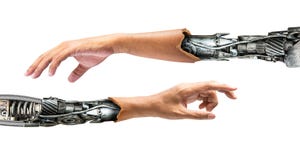

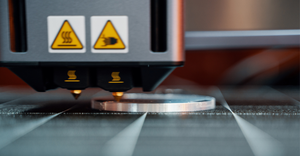

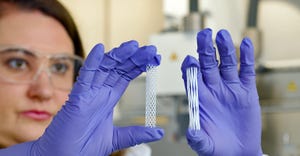

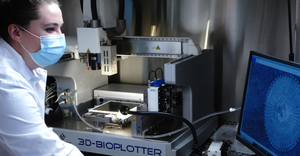

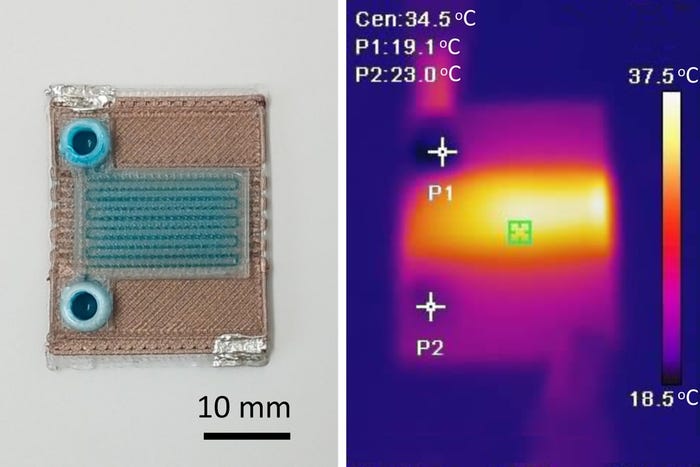

3D-printed implantable lower-limb socket

3D Printing

New Bodies of Work in 3D PrintingNew Bodies of Work in 3D Printing

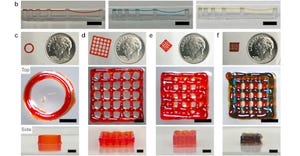

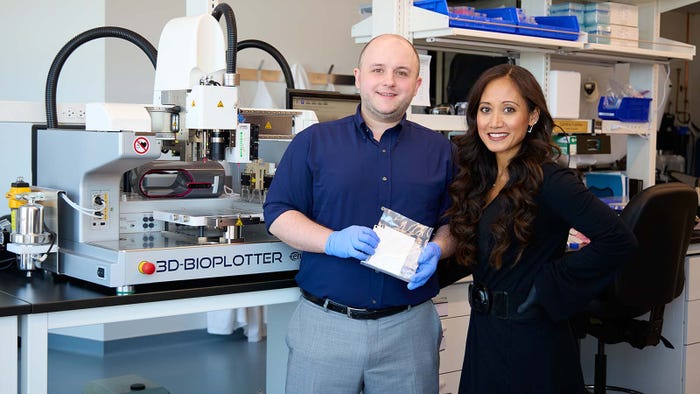

3D printing is taking the manual labor and guesswork out of reconstructive and implantable device design while improving patient comfort.

Sign up for the QMED & MD+DI Daily newsletter.

.png?width=700&auto=webp&quality=80&disable=upscale)