How network design can help medical device manufacturers thrive in a volatile healthcare industry.

April 12, 2016

How network design can help medical device manufacturers thrive in a volatile healthcare industry.

Steve Simco

Medical device manufacturers face an imposing prospect: They must redesign their supply chain network--or, in some cases, create completely new ones--to respond to rising healthcare costs and changing market dynamics.

Network design is no longer a rare event--an ad hoc project to be managed--but something that must be done continuously. In turn, managing and executing network design on an ongoing basis requires a formal organizational capability. In fact, the ongoing upheaval in healthcare makes such a capability a competitive necessity.

Meet with medtech industry suppliers at the MD&M East expo, June 14-16, 2016, in New York City. |

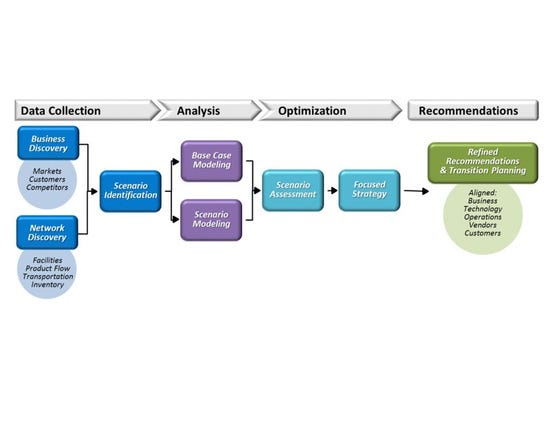

What does this capability look like? At its core is a strategic and repeatable process, the essential elements and flow of which are illustrated in Figure 1. This process enables a company to take the guesswork out of determining which types and sizes of facilities it needs and where they should be located. It replaces gut feel and intuition with a data-rich, fact-based approach to identifying the optimal supply chain network for delivering the desired business results.

Figure 1: High-level supply chain network design process

Data Collection

The process begins with collecting the data required to forge a deep understanding of the company's existing supply chain network. This takes two forms. In business discovery, a company looks to gain clarity on higher-level issues such as the markets it serves, the types of customers it sells to, and key competitors it must fight for business. In network discovery, the focus is more tactical, concerned with such things as product flow and transportation costs.

Combined, business and network discovery give a company insight into key dimensions of its supply chain:

Current state of its assets and facilities (both company-owned and contracted).

Capacity of existing facilities (often a driving factor for a network design initiative).

Operations and process (how things work inside the company's assets and facilities).

Overall performance of the network (including costs and service levels).

Collecting such data is typically the most time-consuming step in the entire process. But it's also the most critical, as it lays the foundation for fact-based decisions about the optimal network design.

Scenario identification and development accompanies discovery activities. During this exercise, a company determines exactly what it will investigate from a network design perspective. For instance, a company that has grown through acquisition and has several more deals on the horizon needs to confirm whether the future acquisitions' facilities should be included in the design. Or, a company with only half of its facilities certified to distribute a particular product must decide if the design should assume the rest will eventually become certified. Such conversations are critical to have at the outset of the process. They help define the scope of the effort which, in turn, ensures the right data is collected.

Data Analysis

Once a company collects the relevant data, it's time for modeling and validation to ensure the data reflects reality--in other words, that the data is as complete and accurate as possible. This "sanity check" is critical to avoid misrepresenting the existing network environment. For example, in one network design effort, a manufacturer inadvertently excluded an entire hospital system from the data collection effort--a fact that only became apparent once the data was modeled. In another, a company was surprised to discover that what it assumed to be its network-wide costs turned out to be significantly lower than the actual costs uncovered when regional cost data was aggregated.

The output of this initial modeling is the base case--the existing network environment. With the base case established, a company can then begin to create possible scenarios to illustrate the resulting impact on network design. By adjusting various constraints--including level and type of demand, desired average cost, geographic location of customers, capacity, and service requirements--the company can determine which types and sizes of facilities it would need and where they should be located to deliver the best business results.

Optimization

After a company develops a number of prospective scenarios, a handful will typically rise to the top as the most potentially desirable. These are the finalists. The company further vets these finalists through additional analysis, eventually determining the one that will best help the company achieve its business goals.

This is a critical exercise, as choosing the scenario to eventually implement is a major strategic decision that can have a massive impact on the business. It's also an iterative process. In some cases, it becomes obvious very quickly which scenario is the best option. But more often than not, a company will require a fair amount of discussion, debate, and adjustments to the scenarios to arrive at the answer.

Recommendations

In the final step of the process, the company further refines the chosen scenario to ensure it aligns with the overall business and its technology, operations, vendors, and customers. Key elements of this exercise include reviewing transition planning and organization alignment (to understand what exactly is involved in moving from the current to future state), sensitivity analysis (to determine how the move may impact other dimensions of the business), and risk analyses (to highlight how the new network design changes the company's risk posture). Addressing these factors enables the company to shape the final recommendation for implementation of the new design.

While the process is the foundation of a formal network design capability, two other elements are vital to making it work.

Tools are needed to model the data. Historically, spreadsheets have been used most often, but their functionality is limited because they don't support the creation and manipulation of sophisticated models. That's why more robust analytical tools--whether custom-developed or packaged--are critical to the kind of advanced network design today's medical supply chains require.

The second element is people: those who actually work on network design efforts. A company must determine which resources should be involved--for instance, an existing operational team or a dedicated analytical resource who may work in marketing, operations, or distribution. It also needs to identify the specific skills those people need to actually do the work--whether those skills already exist in the company or must be brought in from the outside.

Options for Acquiring a Robust Network Design Capability

A formal network design capability is no small undertaking. The key process, tools, and skills that underpin it take time, effort, and money to create and maintain. When considering how to acquire such a capability, medical device manufacturers have three main options: buy, build, or something in between. The right course depends on a variety of factors.

Buy. In the classic "buy" approach, a company can decide to treat network design as discrete projects, defining each project and leveraging consultants and other third parties to help as each projects emerge.

Hybrid. After using external resources for several initiatives, a company may determine that it could benefit from adding some network design resources to its own staff. It could, for instance, create a scaled-down in-house capability comprising mainly an analytics tool and small team to perform ongoing basic modeling. The company would then complement that team with external partners (including consultants and third-party logistics providers) as needed to help with specific projects (such as rationalizing the networks after an acquisition).

Build. Under the "build" model, a company creates a complete in-house capability (possibly in the form of a network design center of excellence) that enables it to quickly jump on any development (e.g., a new acquisition, a divestiture, a new product launch, or a new customer base) to analyze how it will affect the network design and identify any changes needed in response.

Which model is best? As all companies are different, numerous factors could influence the decision. Four are especially important:

How strategic the supply chain is to the company's business. The more a company relies on its supply chain for strategic advantage, the more frequently it would fine-tune or redesign its network. Thus, by extension, the company would most likely want a formal in-house capability it owns and could use on an ongoing basis or to respond quickly to emerging opportunities.

The company's cost appetite. Using third parties on an as-needed basis is generally the least costly of the three models. Thus, it typically would be preferred for companies that lack the budget to make the required upfront investment to build an in-house capability.

The maturity of the company's organization. Building and operating an in-house capability involves a significant learning curve. The challenge is, many medical device manufacturers have not historically had a strong supply chain mindset. Such companies can benefit from the perspective and skills outside resources can bring to the table.

How tactically ready the company is. Many companies lack what's needed on a day-to-day basis to build and operate an in-house capability. For instance, making supply chain-wide network design changes requires end-to-end supply chain data, which most medical device manufacturers typically don't have. That's something third parties can bring to the table.

Cutting across these four factors is another important consideration: the overall complexity of the company's supply chain. Complexity comes in many forms. For instance, a company could have a complex supply chain by virtue of the number of manufacturing and distribution facilities it operates and the carriers it uses, or it might have a high volume of Class III product returns it must manage. Or it could be complex because the company is involved in a highly collaborative outsourcing relationship that must balance different cultures, people, and desired end states. Regardless of the drivers, the more complex the supply chain, the more sophisticated the network design capability the company needs.

Conclusion

It's likely that disruptive change will continue to define the healthcare industry for the foreseeable future. That's why a formal supply chain network design capability--whether it's bought or built--is fast becoming a competitive necessity. It can help medical device manufacturers dramatically reduce costs and improve service levels by, among other things, optimizing their production footprint, product flow, and inventory placement; segmenting demand to align with hospitals' needs and buying behaviors; and rationalizing supply chains as part of M&A activities.

In short, being able to effectively refine and revamp one's supply chain network in concert with changes in supply and demand will be a defining characteristic of winning medical device manufacturers in today's volatile healthcare environment.

Steve Simco is practice director for healthcare at Sedlak Management Consultants. Reach him at [email protected].

You May Also Like