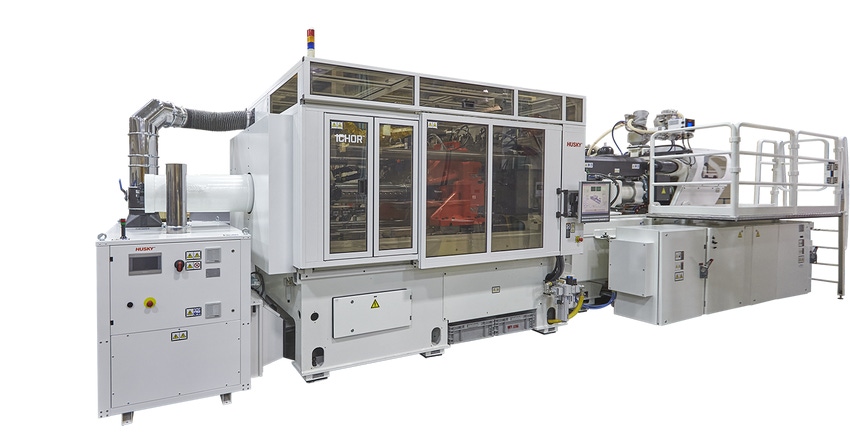

The integrated injection molding system will produce blood collection tubes for the global market.

June 2, 2023

When Husky Technologies celebrated the expansion of its facilities in India in May, it previewed several initiatives that it would roll out in 2023. One of those projects has come to fruition today — installation of the first integrated injection molding system for blood collection tube production in India.

The system has been installed at CML Biotech Ltd., one of the largest blood collection tube manufacturers in the country.

The global blood collection tube (BCT) market was valued at $2.9 billion in 2022 and is anticipated to expand at a compound annual growth rate a tad over 3% from 2023 to 2030, according to a business report from Grand View Research. The growth rate in India, by contrast, is forecast to reach a little over 10% through 2027, according to Entrepreneur India. CML Biotech hopes to capture a large share of that market using Husky’s ICHOR injection molding system equipped with Schöttli precision medical molds. The ICHOR system will enable CML Biotech to improve part quality, weight variations, cycle times, and overall efficiency of the BCT production process, said Husky in the news release.

The first of its kind in India’s medical injection molding industry, the ICHOR system will be monitored in real-time through Husky’s Advantage+Elite predictive monitoring program. This will ensure that the performance of the system is fully optimized, and any potential issues are detected before they impact production, said Husky.

"We sought a trusted supplier, who understood our business and our challenges. We found this in working together with Husky”, said Paul Jacob, managing director of CML Group, in a prepared statement. "It’s not just about producing a BCT for the local market — it is about producing the highest quality BCT in India for the global market.”

The collaboration signifies Husky’s ongoing commitment to transforming the manufacturing process of blood collection tubes, and other medical devices, while making a positive impact on healthcare globally, said Husky.

About the Author(s)

You May Also Like