October 7, 2015

As the medical device industry consolidates, so is the supply base serving them.

|

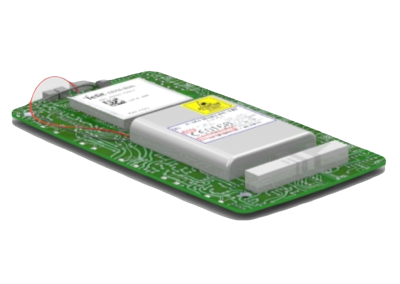

Devicix's offerings include its mHealth Gateway, which the company touts as providing cloud connectivity to a wide array of wireless medical health applications. Now part of manufacturer Nortech Systems, it has the ability to offer even more. (Image courtesy of Devicix) |

Brian Buntz and Chris Newmarker

These days, it seems the entire healthcare industry in consolidating. From hospitals to medical device companies to their suppliers, the healthcare industry field is being dominated by a handful of players. Part of the reason is that healthcare firms' profit margins are falling, leaving them to look for economies of scale to safeguard their business. On top of that, the regulatory complexity along with the inherent challenges of managing large organizations is leading many medtech companies to rely more heavily on contract manufacturers.

And in the medtech field, contract manufacturing is quickly turning into contract development, which ranges from early product design to the manufacture of finished products.

The Demand for the Proverbial One-Stop-Shop

As medical device companies grow bigger and larger, the complexity of running their organization increases, leaving them looking for a growing amount of assistance with product development.

By working with contract firms that can help both with design and development, medical device companies can often realize significant cost savings in the long run. Decisions made early in the design cycle typically end up driving a majority of a finished product's ultimate cost. "The earlier you can look at a design, the earlier you can optimize it for manufacturing," says Tim Hopper, CMO at EG-GILERO. Hopper says that embracing design for manufacturability principles can yield benefits for a spectrum of devices, ranging from those ultimately requiring manual assembly to those manufactured via high-volume automation.

In fact, EG-GILERO was founded with this philosophy in mind. "As the original Gilero Biomedical (www.gilero.com), we mainly worked on early product concepts and designs, which we would take to contract manufacturers," Hopper adds. The main reason we merged with the contract manufacturer Ernie Green Industries (EGI www.egi.net) was so we can offer the full spectrum of design to manufacturing services. You can do certain things up front to make sure the whole process is optimized."

Bill Betten, the director of business solutions at Devicix, an Eden Prairie, MN-based design firm agrees. Such mergers or strong partnerships between design and manufacturing companies provide an important competitive advantage, Betten says.

Devicix itself was recently acquired by contract manufacturer Nortech Systems (Maple Grove, MN).

Such deals, or even strong partnerships between a design outfit and a manufacturing company, bring together the theoretical and practical, according to Betten. "The merger gives the organization the ability to go from A to Z," Betten said Wednesday at MD&M Philadelphia.

Simplifying Supply Chains

The consolidation of contract manufacturers also helps OEMs simplify their supply chains by contracting with contract firms that have a host of capabilities.

"Let's take the Medtronic-Covidien merger as an example," says Hopper of EG-GILERO. "I would imagine those two companies had some overlap in their [supplier] customer base, but many didn't overlap. Medtronic probably doesn't want to have an ever expanding list of suppliers as they make new acquisitions." So for contract manufacturers serving medtech, consolidations of medtech OEMs can lead to similar changes in their business. "Contract manufacturers are having to expand the spectrum of services they offer, and when strategic, make their own acquisitions to make sure they are not cut out."

Betten still stresses the importance of working with suppliers that are the best fit for your particular firm. A supplier that is too big may lack flexibility, while one that is too small may not have sufficient service offerings.

When shopping for a contract manufacturer, Betten recommends "finding that sweet spot between understanding and having the capability, and not being too big and not able to move."

Learn more about cutting-edge medical devices at MD&M Philadelphia, October 7-8. |

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like