A piezoelectric microscope objective nanofocusing device (Z-motor) provides 10× faster response and resolution than classical motor-driven units.

Improvement in the design of medical equipment for better-streamlined functionality and performance is influenced by a number of critical factors. The research, design, modeling, testing, prototyping, and FDA and EU approvals of new mechatronic (mechanical-electronic) devices or iterations usually represents a sizable capital investment of resources well before the equipment goes into serial production. Factored into the medical device’s product development are considerations such as size of the equipment, speed of operation, heat generation, portability, handling of static or kinetic loads, power sources, measuring systems, vacuum and nonmagnetic requirements, sensors, machine controls, component part wear, and diagnostics.

Medical and bioresearch companies involved in product development cycles can capitalize on advances in technology to manufacture devices that operate efficiently and at a low cost. A recent improvement in high-speed laser scanning, for example, has facilitated the release of Harvard Medical School’s latest optical imaging technique, optical frequency-domain imaging (OFDI). OFDI provides highly detailed 3-D visualization of a patient’s coronary arteries. OFDI operates at several magnitudes improvement over its predecessor, optical coherence tomography (OCT), which itself was enabled by advances in laser scanning 15 years ago.

Such refinements in laser scanning technology have had widespread applications. No less influential are recent advances in motor technology, specifically piezoelectric motors and actuators. Medical device manufacturers are increasingly choosing to use piezoelectric motors and actuators instead of conventional electromagnetic motors because they exhibit substantial inherent advantages in medical equipment design. Piezoelectric devices are being used in a range of medical applications including ultrasonic emitters, artificial fertilization, medical nano-microliter pumps, micromonitoring, surgery devices, MRI-compatible robots, microdose dispensing, and cell penetration and cell imaging in cytopathology. The devices are also used in medical material handling such as pick-and-place systems, drug-delivery devices, 3-D scanning, and laser beam steering in ophthalmology, dermatology, and cosmetology.

Piezoelectric Actuators

A piezoelectric actuator (piezo actuator) is a type of solid-state actuator based on the change in shape of a piezoelectric material when an electric field is applied. It uses a piezoelectric ceramic element to produce mechanical energy in response to electrical signals, and conversely, is capable of producing electrical signals in response to mechanical stimulus.

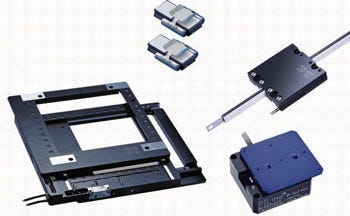

|

Piezoceramic motion control devices such as x-y microscope stage, miniature stage, RodDrive pusher, and subminiature slide are used in biomedical applications. |

The use of piezoelectric materials dates back to 1881 when Pierre and Jacques Curie observed that quartz crystals generated an electric field when stressed along a primary axis. The term piezoelectric derives from the Greek word piezein, meaning to squeeze or press, relating to the electricity that results from pressure applied to a quartz crystal.

Piezoelectric ceramics consist of ferroelectric materials and quartz. High-purity PZT (plumbum, zirconate, titanate) powders are processed, pressed to shape, fired, electroded, and polarized. Polarization is achieved using high electric fields to align material domains along a primary axis. Piezoelectric actuators in their basic form provide very small displacement, but can generate huge forces. The minute size of the displacement is the basis for the high-precision motion these actuators can deliver.

For long travel ranges, a clever arrangement of multiple actuators, or the operation of a single piezoelement at its resonance frequency, have proven to be viable concepts. These types of motion devices are called piezo motors.

The latest designs of piezo motors have a number of advantages over electromagnetic motors when being considered for use in medical equipment and devices. Two types of piezo motors in particular have considerable attributes for medical applications. Ultrasonic piezo linear motors (also called resonant motors) and piezo stepper motors can basically provide unlimited travel (movement), but are very different in their design, specifications, and performance.

In ultrasonic piezoelectric motors, the piezoelectric ceramic material produces high-frequency (inaudible to the human ear) acoustic vibrations on a nanometer scale to create a linear or rotary motion. For large travel ranges, especially when high speeds are also required, ultrasonic linear drives are used. With resolutions up to 50 nm, they are an alternative to electromagnetic motor-spindle combinations. The ultrasonic drives are substantially smaller than conventional electromagnetic motors, and the drive train elements needed to convert rotary to linear motion are not required.

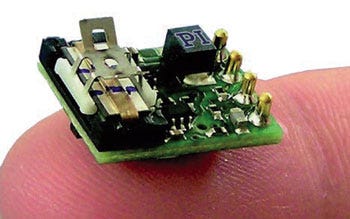

|

A miniature piezo linear motor slide with onboard driver can reach velocities of 200 mm/sec. |

Ultrasonic piezoelectric linear motors employ a rectangular monolithic piezoceramic plate (the stator), segmented on one side by two electrodes. Depending on the desired direction of motion, one of the electrodes of the piezoceramic plate is excited to produce high-frequency eigenmode oscillations (one of the normal vibrational modes of an oscillating system) of tens to hundreds of kilohertz. An alumina friction tip (pusher) attached to the plate moves along an inclined linear path at the eigenmode frequency. Through its contact with the friction bar, it provides microimpulses and drives the moving part of the mechanics (slider and turntable) forward or backwards. With each oscillatory cycle, the mechanics execute a step of a few nanometers. The macroscopic result is smooth motion with a nearly unlimited travel range.

New ultrasonic resonant motors are characterized by very high speeds to 500 mm/sec, in a compact and simple design. Such motors can produce accelerations to 10 g. They are also very stiff, a prerequisite for their fast step-and-settle times (on the order of a few milliseconds) and provide resolution to 0.05 µm.

Piezo stepper linear motors usually consist of several individual piezo actuators and generate motion through a succession of coordinated clamp-unclamp and expand-contract cycles. Each extension cycle provides only a few microns of movement, but running at hundreds to thousands of hertz, achieves continuous motion. Even though the steps are incremental, in the nanometer to micron range, they can move along at speeds in the 10 mm/sec range, taking thousands of steps per second.

Piezo stepper motors can achieve much higher forces of up to 700 N (155 lb) and picometer (one trillionth of a meter) range resolution compared to ultrasonic piezo motors. Resolution of 50 picometers has been demonstrated. The motor is capable of performing high-precision positioning over long travel ranges. And, once the position has been reached, it performs highly dynamic motions for tracking, scanning, or active vibration suppression. Like the ultrasonic piezo motors, these motions can be conducted in the presence of strong magnetic fields or at very low temperatures.

|

Custom ceramic encapsulated piezo stacks are shown here with aperture. |

Basic Piezo Technology for Motion Control Applications

There are a number of different piezo actuators and motor types that are currently available. Here are some of the more common models used in medical device applications.

Simple Piezo Actuator. A piezo actuator expands proportionally to voltage. The motion is basically proportional to the drive voltage. Subgroups include the following:

? Stacked actuator (most common). Characterized by high force, fast response, short travel.

? Shear actuator. Very fast x-y systems are available. Exhibits high force, with the possibility of very high frequency.

Travel is typically limited to 20 µm.

? Tube actuator. Used mostly for micro-dispensing applications and AFM scanners.

? Bender actuator. Can be set for long travel (deflection) to several millimeters, but exhibits low force and low frequency.

Flexure-Guided Piezo Actuator. This has frictionless flexures and motion amplifiers to provide long travel and extremely straight motion. The motion is basically proportional to the drive voltage. Integrated multiaxis systems are available. The motion range is up to 2 mm and above. Expect frictionless performance with no wear and tear.

Ultrasonic Friction Motors. These are based on high-frequency oscillation of a piezo plate (stator). They have unlimited motion, high speed, and fast response (10 milliseconds). The oscillation is transferred to a slide or rotor via friction. Because of the friction, however, resolution is limited to typically 50 nm.

Piezo Stepping Motors. Stepping motors have basically an unlimited motion range. These are based on the accumulation of small controllable steps. Other attributes are as follows:

? Picometer resolution dither mode (direct piezo actuation).

? Compact and high force to 155 lb (for off-the-shelf units).

? Fast response (less than 1 millisecond). Very high stiffness.

UItrasonic Transducers. Ultrasonic transducers are plate or disk-driven with a high frequency at resonance. They are often used as sensors or transmitters and are used in nebulizers.

Improving Medical Equipment Performance

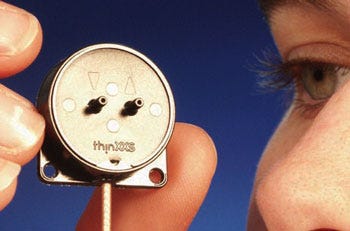

|

Piezoelectric disk actuators such as the one in thinXXS Microtechnology AG micropump 2000s are custom components. In this device, the actuators precisely dose liquids and gases. |

Medical devices can be made smaller, more precise, lighter, and easier to control by employing piezoelectric motors (see the sidebar, "Piezoelectric Devices Used in Medical Equipment").

High Force Generation Supports Miniaturization. Piezoelectric motors are suited for miniaturization. They can easily be made smaller and more compact than electromagnetic motors, yet for their size they provide greater force. The efficiency of electromagnetic motors falls as dimensions are reduced, with more of the electrical power converted to heat. In contrast, piezoelectric motors exhibit nearly constant efficiency. Being the same volume and weight, the stored energy density of a piezo motor is 10 times that of an electromagnetic motor. The most advanced versions of piezo motors are configured into extremely compact, high-speed micropositioning stages that are smaller than a matchbox—the smallest piezo motor–driven stages are currently being used in autofocus devices for cell phone cameras. Because piezo motors provide a higher force per motor size, they enable medical devices to be reduced in size, while maintaining or increasing performance.

Animation demonstrates a piezo stepping linear motor. |

Positioning Accuracy. The direct-drive principle of the piezo motor eliminates the need for a supplementary transmission (or gear train) found in conventional electromagnetic motors. This avoids the usual backlash effect that limits accurate tracing, thereby creating a critical reduction in positioning accuracy in electromagnetic servomotors. The mechanical coupling elements otherwise required to convert the rotary motion of classical motors to linear motion are unnecessary. The intrinsic steady-state auto-locking capability of piezoelectric motors does away with servo dither inherent in electromagnetic motors. Piezo motors can be designed to hold their positions to nanometer accuracy, even when powered down.

Fast Acceleration. Piezo devices can react in microseconds. Acceleration rates of more than 10,000 g (response times of 0.01 milliseconds) can be obtained.

No Magnetic Fields. For medical and biotechnology applications, piezoelectric motors are suitable because they do not create electromagnetic interference, nor are they influenced by it. This characteristic eliminates the need for magnetic shielding, which is particularly important for motors used within strong magnetic fields, such as with MRI equipment, where small piezo motors are used for MRI-monitored microsurgery and large piezo motors for rotating patients and equipment. Magnetic fields and metal components in conventional electronic motors make it impossible for motorized medical devices to function within MRI equipment.

No Maintenance or Lubrication, Aseptic Enabled. Because piezo motion depends on crystalline effects and involves no rotating parts like gears or bearings, the motors are maintenance free and do not require any lubrication. The parts can be sterilized at high temperatures, which is a significant advantage in medical applications.

Reduced Power Consumption. Static operation, even with heavy loads being held for long periods, consumes virtually no power. Also, because the efficiency of piezoelectric motors is not reduced by miniaturization, they are effective in the power range lower than 30 W. This makes piezo motors attractive for use in battery-operated, portable, and wearable medical devices.

No Heat Generation. At rest, piezo motors do not generate heat. They also eliminate servo dither and the accompanying heat generation.

Vacuum-Compatible. Piezo motors are in principle vacuum-compatible, a requirement for many applications in the medical industry.

Operable at Cryogenic Temperatures. Piezoelectric motors continue to operate even at temperatures close to 0°K, making them suitable for operation in extremely cold environments, such as in medical laboratory storage facilities and in cryogenic research.

Flammability. Piezo motors are nonflammable and therefore safe in the event of an overload or short circuit at the output terminal, a considerable advantage for portable and wearable medical devices.

Power Generation. Piezo devices can be used to harvest energy. For example, using a person’s motion to power small medical or electrical devices such as pacemakers or health monitors.

Conclusion

Electromagnetic devices dominate the drive mechanisms in medical equipment designs today. However, increasing accuracy requirements in the micron and nanometer ranges, along with an inclination to miniaturization, dynamics streamlining and interference immunity are pushing the physical limitations of electromagnetic drive systems. Piezoelectric motors may prove to be a viable alternative, finding their way into a growing number of medical device applications.

Jim McMahon is a technical writer with Zebra Communications. Stefan Vorndran is director of corporate product marketing and communications for Physik Instrumente LP (Auburn, MA).

About the Author(s)

You May Also Like