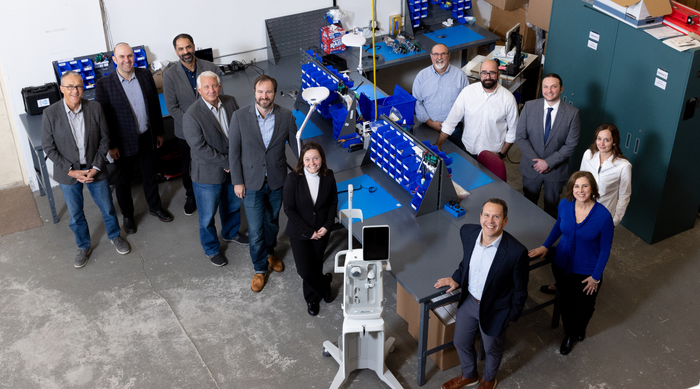

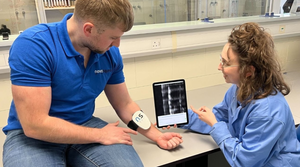

Photo of Reprieve Medical team with the company's diuretic and fluid management system for acute decompensated heart failure.

Startups

New Cardiovascular Company Emerges from Stealth ModeNew Cardiovascular Company Emerges from Stealth Mode

Fresh off a $42 million series A financing, Reprieve Medical is developing an intelligent automated fluid management system for heart failure patients.

Sign up for the QMED & MD+DI Daily newsletter.

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)