September 21, 2016

Polymer extruder Zeus has created catheter polymer braiding with tensile strength comparable to metallic braiding, enabling MRI to be used during catheter based procedures. The innovation won this year's MD&M Minneapolis Innovation Prize.

Chris Newmarker

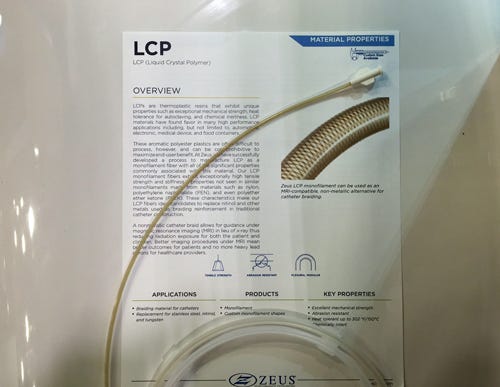

Zeus (Orangeburg, SC) on Wednesday won the MD&M Minneapolis Innovation Prize among exhibitors with the non-metallic catheters it is enabling through LCP monofilament fiber launched at the show.

Having catheters without metallic braiding enables MRI imaging during procedures. Not only is MRI superior in some respects to the fluoroscopy presently in use, but it lowers radiation exposure risks for both patients and doctors, Irina Roof, PhD, Zeus's staff material scientist, explained to the innovation tour group that selected the contest winner.

To achieve this, Zeus figured out how to do something that Roof says had not been achieved before, extruding and braiding liquid crystal polymer (LCP) in a way that it retains properties associated with the matierial. Roof declined to disclose how the company specifically achieved this.

The result, though, was impressive: Zeus says it LCP fiber has an average tensile strength of 1.2 Gpa, compared to 1.0 Gpa for 304 stainless steel (annealed). The fiber also provides excellent torque response, pushability, and distal end deflectability.

The innovation beat out other finalists including a vacuum-based decontamination floor mat from Circuit Solutions (Minnetonka, MN), 3-D printed rapid prototyping molds from Diversified Plastics (Minneapolis), a super precise knife barrel hinge from Liquidmetal Technologies (Rancho Santa Margarita, CA), and a mobile health-based breast cancer screening solution from Pressure Profile Systems (Los Angeles).

One major properties difference between the LCP fibers from Zeus and the steel is that average elongation at break is 1.7% for the LCP, versus 31.1% for the steel. But Roof says it is the tensile strength that is most important to catheter manufacturers.

The LCP monofilament is braided over a catheter base liner during construction to provide mechanical strength and support, with the braiding then covered with a layer of Pebax or another nylon jacketing material reflowed under heat shrink

The reflow and bonding process causes the braiding to become fused between the nylon bonding material and underlying liner, achieving structural reinforcement. Zeus's proprietary processes are able to create a fiber with extremely low potential for fraying.

Chris Newmarker is senior editor of Qmed. Follow him on Twitter at @newmarker.

Like what you're reading? Subscribe to our daily e-newsletter.

[Image by Chris Newmarker/Qmed]

About the Author(s)

You May Also Like