October 14, 2014

While robotic systems have revolutionized assembly, they traditionally haven't been so good at collaborating with others, meaning non-robotic human workers. In fact, it is often dangerous for people to even be near many assembly robots, which are often housed in cages, as we described in a recent post titled "Will Your Next Coworker Be a Robot?" In addition, such systems have been inflexible and difficult to reprogram.

|

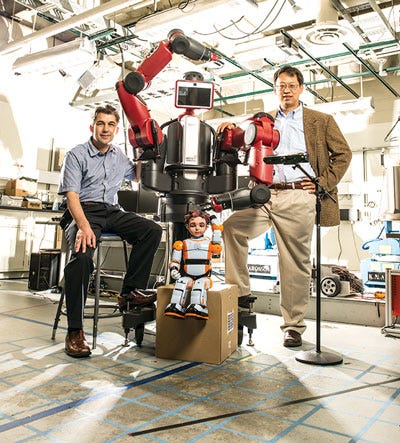

Rensselaer professors Jonas Braasch and John Wen stand next to Baxter in the fall of 2013. Image from Rensselaer. |

But all of that is changing, as a recent PwC report titled "The new hire: How a new generation of robots is transforming manufacturing" observes. Robot makers are making their systems safer and easier to program. Traditionally, programming a robot had to be done with someone with an engineering background.

In the past several years, several collaborative dual-arm robots have debuted, including the Yasakawa Motoman SDA10D (the so-called "Dexter Bot), the YuMi ABB Dual Arm Robot, and the Baxter robot from Rethink Robotics.

Baxter is already used by a number of medical device companies. In addition, Baxter is also the subject of medical research. For instance, Rensselaer professors John Wen and Jonas Braasch have affixed Baxter to a motorized wheelchair, that can be remote controlled by a paralyzed patient using a device known as a Jamboxx, a harmonica-like user interface. The resulting system, dubbed a "Jamster," has a price tag of $26,000--significantly less than the $400,000 cost of other assistive robotic systems.

MPMN recently had the opportunity to correspond with Anthony Robson, hardware product manager at Rethink Robotics (Boston), which is the creator of Baxter, a robot designed to work alongside people, which resulted in this Q&A.

MPMN: Can you summarize how Baxter can be programmed and how that process is getting progressively easier?

Robson: Baxter doesn't require an engineering degree to be able to train it to do a meaningful task. In fact, we don't even use the word "programming" when describe the process. Instead, users 'train' the robot by moving its arms and manually showing it what to do.

We are continually working with our customers, observing how they use Baxter, learning what works and what's intuitive to our typical users, then implementing software improvements every 3-4 months to make the process easier. The process usually involves setting up any signals for coordinating Baxter with any external machines, devices or sensors, using the build in interface on the arm and screen. Then, using the teach-by-demonstration features of Baxter, you train Baxter the sequence of operations to perform the task. Finally, the task is tested, refined, and coordinated/synchronized with the signals to achieve the desired result. For example, it used to take four or five steps to configure a signal on a pick, but now with one click you can get to the I/O settings. Lately, we have been focused on reducing the time it takes for users to re-deploy the robot across multiple tasks. You will see some improvements in our next software release in November that help in this area.

MPMN: Can you summarize Baxter's safety features and provide a couple of examples of how the robot is being used in collaborative situations that would have been previously for humans nearby.

Robson: Baxter is classified as a robot that is power and force limited by inherent design in the industrial robot safety standards. Baxter's power/force is limited by our careful choice of motors, gear ratios that keep the maximum capabilities of the robot far lower than that of traditional industrial robots, and the use of patented Series Elastic Actuators at every joint to allow us to precisely control Baxter's behavior. Unlike pretty much every other industrial robot, Baxter's arms are not rigid and readily flex on contact, as each joint incorporates a spring for compliance and force sensing. The joints are also easily backdrivable, meaning you can simply push Baxter away - there is no danger of being clamped or squeezed by Baxter. Of course Baxter is only one part of a robotic work cell, so we provide a lot of support to our users as they follow the ISO/ANSI industrial robot safety standards and perform a risk assessment for their application considering the system as a whole.

MPMN: How do most companies use Baxter?

Manufacturers tend to use Baxter to free up people from repetitive tasks so that they only need to approach the robot to supply raw parts or remove finished parts. Many times you will see a person nearby Baxter working on a complex assembly task that requires human-level dexterity, while Baxter manages the machine producing the parts. Many times that same operator is responsible for Baxter, too--stopping and starting the robot overnight for example. There are a lot of applications where the cycle time is just short enough that a person can't step away to do something else, and is forced to wait for a part to be produced or tested or processed. Baxter allows the operator to support many machines each tended by a Baxter robot. Another example is case packing where Baxter keeps up with the flow of parts, while the person only needs to stop by once in a while to top up the supply of boxes.

Refresh your medical device industry knowledge at MD&M Chicago, October 15-16, 2014, and MD&M Minneapolis, October 29-30, 2014. |

Brian Buntz is the editor-in-chief of MPMN and Qmed. Follow him on Twitter at @brian_buntz.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like