March 18, 2015

A company started by UNC-Chapel Hill professors touts its new Terminator 2-inspired CLIP technology that promises printing speeds 25 to 100 times faster than conventional 3-D printers.

Chris Newmarker

|

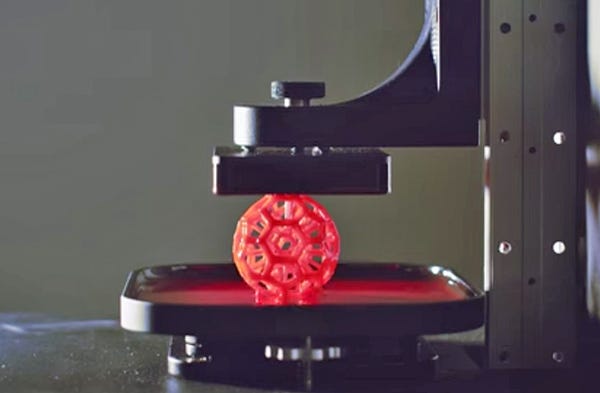

CLIP technology in action. (Image courtesy of Carbon 3D Inc.) |

Updated March 23, 2014

Picture a polymer object literally rising out of a pool of liquid media in minutes rather than the hours it would take for a traditional 3-D printer to lay down material.

That is exactly what researchers out of the University of North Carolina at Chapel Hill claim to have accomplished. They are now focused on bringing the technology, called Continuous Liquid Interface Production (CLIP), to market through their Silicon Valley-based startup Carbon3D Inc.

The technology was actually inspired by the movie Terminator 2 and the way the next generation T-1000 robot assassin rises out of a puddle of material, Joseph M. DeSimone, PhD, said during a recent TED talk. "We thought, 'Why couldn't a 3-D printer operate in this fashion, where you have an object arise out of a puddle in essentially real time with essentially no waste to make a great object,'" said DeSimone--a professor of chemistry at UNC-Chapel Hill and of chemical engineering at N.C. State, and presently CEO of Carbon3D.

With $51 million in venture capital funding behind them, they're already touting the technology's potential in the medical device and drug delivery industries.

"Since CLIP facilitates 3-D polymeric object fabrication in a matter of minutes instead of hours or days, it would not be impossible within coming years to enable personalized coronary stents, dental implants or prosthetics to be 3-D printed on-demand in a medical setting," DeSimone said in a UNC-Chapel Hill news release.

The technology is slated to be featured as the cover story in the March 20 print issue of Science, according to UNC-Chapel Hill.

So how does this process work? The CLIP technology is all about carefully balancing the interaction of ultraviolet light, which triggers photo polymerization, and oxygen, which inhibits the reaction. In the process, an object can be "grown" out of a pool of resin.

Carbon3D explains on its website that the key to this process is a special window that is transparent to light and permeable to oxygen, much like a contact lens.

The company goes on to explain: "By controlling the oxygen flux through the window, CLIP creates a 'dead zone' in the resin pool just tens of microns thick (about 2-3 diameters of a red blood cell) where photopolymerization cannot occur. As a series of cross-sectional images of a 3D model is played like a movie into the resin pool from underneath, the physical object emerges continuously from just above the dead zone."

Carbon3D claims that CLIP can produce a 51 mm-diameter complex object in 6.5 minutes, versus 3 to 12 hours with traditional 3-D printing. DeSimone envisions the technology could eventually 3-D print objects 1000 times faster than what is presently possible as the ability to deliver liquid improves. DeSimone looks forward to the time when the machines will need to be water-cooled because they are going so fast.

Objects produced can have feature sizes below 20 microns, or less than one quarter of the width of a piece of paper. Plus, CLIP-made objects are more like injection-molded parts in that they have consistent and predictable mechanical properties, smooth on the outside and solid on the inside, according to the company.

In addition, a wider range of materials can be used in the process, including elastomers, silicones, nylon-like materials, ceramics and biodegradable materials, UNC-Chapel Hill reported. "We're able to throw the entire polymer chemistry textbook at this. We're able to design chemistries that give rise the properties you really want in a 3-D printed object," DeSimone said in his TED talk.

"When we met Joe and saw what his team had invented, it was immediately clear to us that 3-D printing would never be the same," Jim Goetz, a Carbon3D board member and partner at one of its backers, Sequoia Capital, said in a company news release.

Check out this video of CLIP technology in action:

Refresh your medical device industry knowledge at BIOMEDevice Boston, May 6-7, 2015. |

Chris Newmarker is senior editor of Qmed and MPMN. Follow him on Twitter at @newmarker.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like