August 19, 2016

It doesn't have a snazzy name yet. But researchers at top universities have been making strides with custom-built 3-D printers that create with multiple materials from the nanoscale to the macroscale--enabling significant medical device innovation in the process.

Chris Newmarker

|

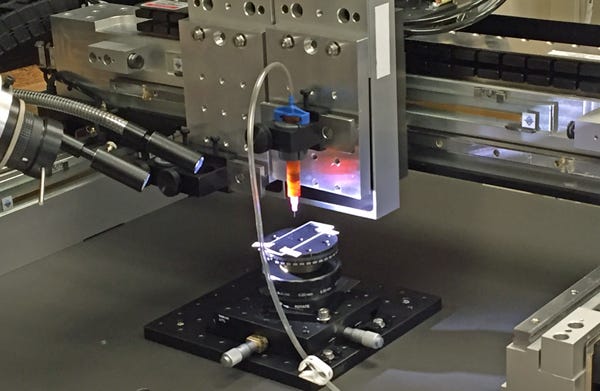

Researchers led by Michael McAlpine at the University of Minnesota have custom-built 3-D printers that are able to create at micron-level details using multiple materials, including living cells. (Photo by Chris Newmarker/Qmed) |

Could people someday be able to print entire customized medical devices at home? Michael McAlpine at the University of Minnesota thinks so.

"I don't see any reason why 10 years from now a person at home can't print their own electronics, print their own medical device that's completely custom-built to the geometry of that person," says McAlpine, a mechanical engineering professor who has been one of the pioneers when it comes to building custom 3-D printers able to create complex shapes with multiple materials, including living cells.

It has only been in recent years that McAlpine and others such as Jennifer Lewis, ScD, at Harvard University and Anthony Atala, MD, at the Wake Forest Institute for Regenerative Medicine, have started creating custom 3-D printers that are far more complex than what is presently commercially available.

Think printers with an XYZ platform, building with multiple nozzles delivering multiple materials, and creating computer software that enables the weaving in of the various materials to take place at the micron level.

It involves a wide range of sizes, too: The materials being used might be engineered at the nanoscale, printing through nozzle syringe tips then takes place at the microscale, and the eventual creation takes place at the macrolevel.

McAlpine thinks someone needs to come up with a more exciting name for the technology. For now, he calls it "multi-material, multiscale" 3-D printing. McAlpine and his research colleagues have been able to achieve some major innovations with such printing technology, first at Princeton University and in the past year at the University of Minnesota:

|

This 3-D printed nerve regeneration guide was able to improve a rat's walking ability. (Image courtesy of McAlpine Research Group/University of Minnesota) |

1. Nerve Regeneration

Last year, McAlpine and his colleagues announced that they had been able to improve a rat's walking ability by using a 3-D scanner to reverse engineer the structure of the rat's sciatic nerve, and then 3-D print a silicone regeneration guide that also had 3D-printed chemical cues to promote both motor and sensory nerve regeneration. Implantation of the guide in the rat provided a proof-of-concept that such guides could promote nerve regeneration. McAlpine envisions such guides someday being made of bioabsorbable materials, enabling nerve regeneration that is usually rare among people suffering from nerve damage.

2. Entirely Printed Electronic Devices

Another recent innovation involves what McAlpine thinks is the first time a semiconducting device was entirely 3-D printed. McAlpine and his collaborators created a hard plastic contact lens embedded with LEDS made out of nano-sized crystals called "quantum dots." They were able to generate two different colors, orange and green. They've also been able to create a cube embedded with multicolor LEDs. McAlpine thinks 3-D printing could someday create complex electronics embedded inside contact lenses--far more than what is presently possible. He notes that the printing processes he's been using are often at room temperature, with the plastic hardened through curing, enabling much more intricacy in the embedded electronics. (McAlpine noted that his team inadvertently finds itself making scientific discoveries, that some of the discoveries they've made about curing processes would be entire scientific papers for material science researchers.)

|

McAlpine holds an LED 3-D printed onto curved glass. (Image courtesy of Frank Wojciechowski/Princeton University) |

3. Bionic Ear

|

McAlpine and his colleagues have been able to print a living ear along with embedded electronics, creating a "bionic ear." (Image courtesy of McAlpine Research Group/University of Minnesota) |

McAlpine and other researchers at Princeton a few years back printed a bionic ear out of living cells, also printing an antenna embedded in the ear that could receive radio signals. McAlpine acknowledges the ear itself was fairly crude: "It was engineers doing tissue engineering." But it provided another proof-of-concept, that printing living organs along with embedded electronics at the same time is possible. Since then, a research team led by Atala at Wake Forest developed a 3-D bioprinter able to print replacement tissue including ears that has the strength needed to be potentially implanted in people.

McAlpine is excited about what he could potentially accomplish at the University of Minnesota because the program there has people with a variety of specialties integrated around the 3-D printing approach. One student, for example, was able to work out alignment markers and camera systems so that, for example, they could replicate a 3-D printing run again and again. "Some have been good at software, so they've been improving the programs. Others know materials," McAlpine said.

Being located in one of the top three medical device hubs in the United States has also created an endless number collaborative opportunities, McAlpine says.

McAlpine is especially optimistic about the medtech potential of 3-D printing because he think the science is already there. "These are engineering problems versus fundamental science problems."

The field also needs more injections of creativity and outside-the-box thinking, according to McAlpine. Bioprinting a human heart? "Maybe instead of making it as close to the human heart as possible, maybe you want to introduce electronics so that it pumps better than the human heart. Maybe it doesn't even look like a human heart. Maybe you don't even need cells."

McAlpine muses that perhaps we may want to outdo nature itself: "Maybe the goal shouldn't be to make something that is as closely as possible to the actual organ. Maybe the goal should be to rethink it and do something different."

Chris Newmarker is senior editor of Qmed. Follow him on Twitter at @newmarker.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like