November 4, 2015

An affordable professional-grade 3-D printer wowed the Innovation Prize tour group on Wednesday at Minnesota Medtech Week.

Chris Newmarker

|

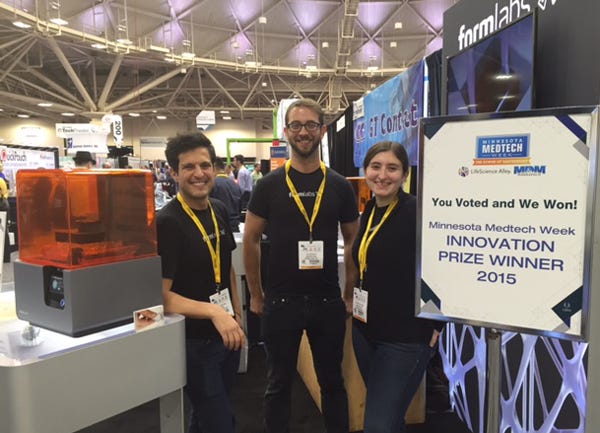

From left to right, the Form 2 3-D printer, Jory Block of Formlabs sales, JP Shipley of Formlabs marketing, Teresa Atwood of Formlabs operations, and the sign touting their winning of the Minnesota Medtech Week Innovation Prize. (Photo by Chris Newmarker) |

Formlabs (Somerville, MA), which has a professional grade 3-D printer called the Form 2 that costs $3,499, won the Minnesota Medtech Week Innovation Prize on Wednesday after impressing a tour group of attendees at the Minneapolis show.

The Form 2 uses a precisely guided laser to cure a photopolymer resin. The company boasts that the technology allows for unprecedented accuracy and precision at a price point which almost everyone can afford. Such stereolithography 3-D printing technology has run in the tens of thousands of dollars in the past.

Other Minnesota Medtech Week Innovation Prize finalists included Heraeus Medical Components (St. Paul, MN), which has a new biocompatible ceramic and platinum-based CerMet paste that can be precisely layered to create complex, 3-D housing for implantible medical devices. Finalist Sunstone Engineering (Payson, UT) boasted its affordable Orion 200i2 micro TIG (pulse arc) welder, able to control a wide range of power in order to permanently fuse together metal as fine as a piece of hair. Compounding Solutions (Lewiston, ME) in September 2014 introduced its Mobilize lubricious, friction-reducing additive that could reduce the need for polymer coatings on some devices. And finalist Zeus (Orangeburg, SC) touted FluoroPEELZ, a fluoropolymer heat shrink that operators can easily peel rather than cut off from the catheter shaft after the reflow heating process in which the inner layers of the catheter are combined.

The Form 2, though, was tops with the tour group. The Form 2 excels at producing intricate parts, thanks in part to its ability to use laser light to cure resin. TechCrunch referred to the Form 2 as the first refined consumer-grade SLA printer whereas it calls the Form 1 "a prototype for a consumer-grade SLA printer."

Says Formlabs: "When a designer has a highly accurate prototyping tool right at their desk they're able to more quickly iterate on designs and cut time to market by a matter of months, if not years."

Here is video of JP Shipley, a Formlabs marketing professional, demonstrating the Form 2 last month at MD&M Philadelphia:

Chris Newmarker is senior editor of Qmed and MPMN. Follow him on Twitter at @newmarker.

Like what you're reading? Subscribe to our daily e-newsletter.

About the Author(s)

You May Also Like