How to Build a Better Surgical Hand Tool

Here’s how engineers can design surgical hand tools that are smaller and quieter, with longer battery life and a few other end-user-requested features.

October 14, 2023

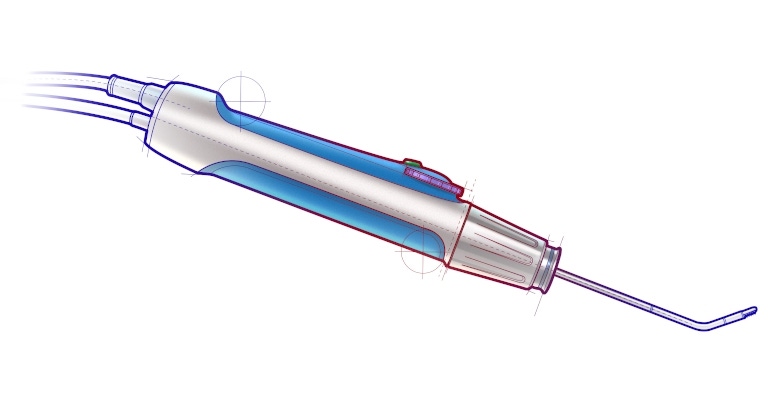

Surgical hand tools are used in a wide variety of surgical applications, including arthroscopic, orthopedic, spinal, neurological, and ENT (ear, nose, and throat) procedures as well as in reconstructive and plastic surgeries, Paul Schonhoff, senior industry manager for Portescap, tells Design News.

Demand for such tools is growing significantly. Grand View Research valued the global market for hand-held surgical instruments to be about USD 5.48 billion in 2022 and believes it will grow annually 7.3% from 2023 to 2030. The orthopedic sector is the largest sector, but others like plastic surgery may be seeing faster growth, according to Grand View.

To meet end-user needs in this growing surgical space, Design News asked Schonhoff a few questions about developing better surgical hand tools.

What challenges do users face today, and how could better surgical hand tools help users address such challenges?

Paul Schonhoff: Surgeons are asking for tools with improved battery life, less vibration, quieter operation, and less heat, but within increasingly smaller envelopes. Improved surgical hand tools would decrease surgeon strain and discomfort, due to an improved ability to hold and operate the tool for extended periods of time, as well as lead to improved patient outcomes, including less scarring, reduced blood loss, and a shorter recovery time.

What challenges do engineers designing such tools face, and how can they be addressed?

Schonhoff: The main challenge facing design engineers is how to balance the above requests while maintaining (or improving) tool performance within a smaller, more ergonomic package. Designs with increased efficiency and higher power density are the ideal outcome, as well as the inclusion of features like adjustable grips, lighter weight, and greater durability and robustness, which allows for prolonged use without loss of efficiency or accuracy.

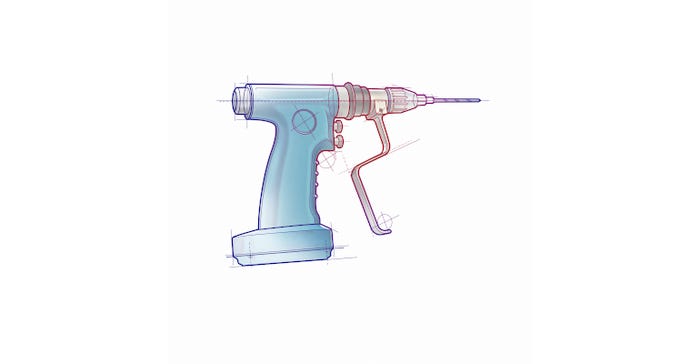

How can speed and torque be controlled easily by users?

Schonhoff: Controlling the speed and torque of a surgical hand tool is crucial in medical procedures to ensure precision and patient safety. The controller is onboard the surgical hand tool and usually features variable speed triggers or has a slide adjustment that allows the user to adjust the device’s speed and rotation.

How many speed and torque settings should be offered on such tools?

Schonhoff: It varies by design, but typically two to three settings should be offered; variable speed settings are also an option.

What are the features and benefits of closed-loop speed capabilities compared with those of open-loop speed capabilities?

Schonhoff: Open-loop speed control is ideal when a higher speed at no load operation for a given voltage is required. Closed-loop speed control is used under load to maintain the device’s speed.

How do voltage and current options impact the design of such tools?

Schonhoff: The design of the tool, including the motor and gearing system, needs to be optimized to handle the chosen voltage and current while delivering the desired performance. This is usually determined by the battery voltage/size and working points. It’s important for a motion solutions provider to be able to customize the device to meet customer requirements.

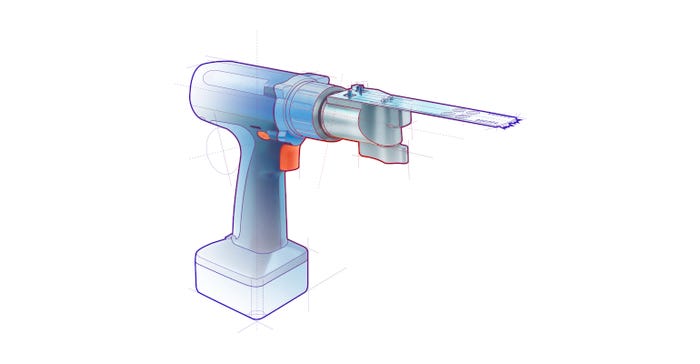

Should these devices be corded or cordless? How does this decision impact motor selection?

Schonhoff: We have seen an industry shift to cordless. Ease of maneuverability and use, decreased clutter in the operating room, and improved ergonomics are only a few of the reasons for the shift. Cordless also ensures that the tools can continue to be used in cases of emergencies like power outages.

The choice of motor for cordless surgical hand tools must balance power output, efficiency, size, weight, noise, and reliability. The motor should be carefully selected to align with the specific requirements of the tool, the types of procedures it will be used for, and the ergonomic needs of the medical professionals who will be using it.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)