Your Most Pressing Steerable Catheter Design Questions Answered

An expert at Teleflex Medical OEM answers technical questions about steerable catheter design and engineering for structural heart applications.

September 21, 2023

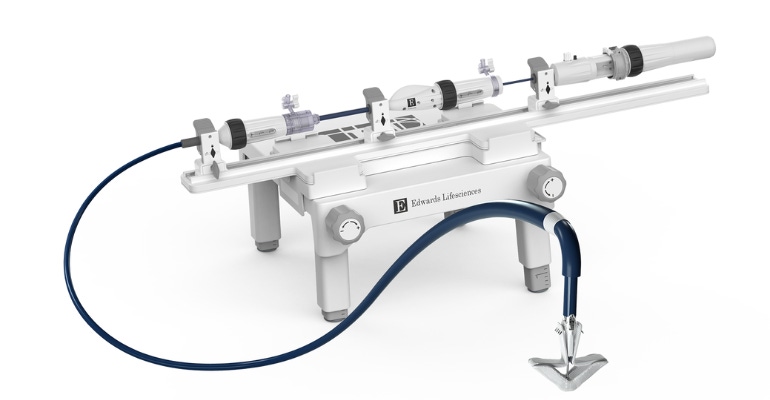

Complex catheters are used to perform an ever-increasing number of interventional and diagnostic procedures. There are quite a few steerable catheter design and engineering considerations, especially for procedures like transcatheter aortic valve replacement (TAVR).

Philip O'Malley, an R&D manager at Teleflex Medical OEM based in Limerick, Ireland, led a MD+DI webinar, "Steerable Catheters and Their Role in Structural Heart Applications," in May, which is available on demand. O'Malley has 26 years of experience in the medical device industry.

Key takeaways from the webinar

TAVR: Also known as transcatheter aortic valve implantation (TAVI), TAVR is a common structural heart procedure that uses a steerable catheter. It involves delivering a device through the femoral artery, navigating it over the aortic arch, and positioning it above the native valve.

Anatomical challenges: Structural heart procedures, like TAVR, pose specific challenges due to the complex anatomy of the heart. Precisely positioning the catheter tip is difficult, especially in beating hearts, and patient respiration adds to this challenge.

Torturous vessels: The vessels through which the catheter must navigate can be torturous, adding to the complexity of the procedure.

Three-dimensional space: Operating within the three-dimensional space of the heart is challenging as it lacks adequate vessel or anatomical support for steering (hence the need for steerable catheter design and innovation).

Delivery system strength: TAVR delivery systems must withstand high tensile forces due to the procedure's requirements. Over time, these systems have become smaller in French size, while valve offerings have grown larger, leading to increased challenges.

Material properties: To resist high radial forces, delivery systems require materials with high tensile yield, resulting in stiff and inflexible systems. Consequently, significant steering forces are needed to maneuver these delivery systems.

Evolution of steerable catheters: Steerable catheter design and development has advanced over the last 70 years, but challenges with delivery systems remain. Further innovation is needed to integrate polymer and metal components and provide customized solutions for mitral valve therapies.

Catheter design knowledge: Combining a deep understanding of steerable catheter design with innovative solutions can drive advancements in structural heart steerable catheter design and engineering. It also helps to have a deep understanding of the procedure in which the device will ultimately be used.

Expectations for future innovation: O'Malley anticipates continued improvement and innovation in the field of structural heart steerable catheters as more research and development efforts are dedicated to addressing the challenges.

Steerable catheter design Q&A

O'Malley answered plenty of interesting questions about steerable catheter design and engineering during the live webinar, such as:

What are the design considerations for steerable catheters that have outer dimension profile changes along the length? How do you go about routing the pull wire through different shaft diameters?

O'Malley: It is possible to do that, to embed the pull wire in the wall of the catheter where there's a change in dimensions. It's based on how we manufacture the catheter, but I just say that it is possible to do that.

What are the design considerations for the distal end of the catheter for visualization under fluoroscopy? Are marker bands the only option?

O'Malley: Generally, marker bands are used because these delivery systems can be quite big. You can use a loaded metal filler powder that's compounded into the actual polymer materials which are effective in visualization under fluoroscopy, so that's another option.

Do you have any thoughts on hydraulically driven steerable catheters?

O'Malley: Yeah, it's interesting. I suppose what we talked about today was on mechanical systems. Hydraulics … potentially there are innovations around that area. I would [urge caution] around safety of high-pressure fluid systems and use within the coronary area. It's an interesting approach.

How does the catheter pierce the septum wall?

O'Malley: Generally, a small-gauge needle is used to pierce the septum wall. Sometimes people use an RF needle as well to reduce the force for going through the wall. And then the delivery system then follows that, so the delivery system then is used to kind of dilate that initial crossing.

What material trends are you seeing?

O'Malley: Obviously we want our materials to be flexible, but we also want them to be very strong in tension and compression. So, materials that give you these kinds of properties are definitely notable. It's really, I would say, the combination of integration of metal components into commonly used thermoplastics that we're probably seeing more innovation around than actually the materials themselves.

Do you feel polyether ether ketone (PEEK) can provide the stiffness needed to give that degree of freedom in connection with metals?

O'Malley: Yeah definitely, PEEK is a great material and it's often touted as a good metal replacement polymer. Probably some of the watch outs for a design for manufacturability point of view is the ability to bond PEEK to other substrates or to process PEEK. It's definitely a good metal replacement alternative for sure and we do see that material has been useful in structural heart delivery systems for sure.

How is the pull band secured to the pull wire? Does the pull band double up as a marker band?

O'Malley: Normally for these high-force applications you're trying to generate a very high connection between the pull wire and the pull band, generally they're welded together so you get your strongest bond when you weld materials of a similar nature so if it is a stainless steel wire the pull band is generally a stainless steel, but what you're really looking for there is a really strong weld, so picking similar materials is always a good idea. In terms of using it as a marker band it's dependent on the thickness, but it is visible under X-ray for sure. Probably not as visible as a platinum or a gold, but nevertheless you can see it.

You mentioned laser cut hypos as the next step in flexible delivery catheters what types of laser cut patterns do you see as the most promising?

O'Malley: The shape that you want to create on the end of your delivery system will dictate the type of pattern that you want to create or use. It's very dependent. If you can imagine a situation where you're trying to deflect the catheter on a single plane, then you will pick a laser cut pattern that will only deflect in one plane. But if you want something where there's high degrees of freedom, you want to deflect in lots of different planes, then the selection of the pattern will be different. So, it's very much dependent on what you want to do with that delivery system.

What are your thoughts on moving from steerables to a pre-bent system?

O'Malley: It probably is doable from a point of view of simpler procedures like the TAVI, we've seen that there. Obviously where you have situations in the mitral system where you have quite stiff catheters and you're trying to deflect them as we've seen in the mitral system where they have to go across the atriums and then down into the mitral valve it's more difficult to have a pre-shaped system. So, I never say no until you try something, but I still think steerables have a huge role to play there. Pre-shaped, I think, there’s probably limitations around.

Other than the steering pull wire, have you considered other steering concepts?

O'Malley: For high-force applications, the steering wire concept is still the go-to option, especially for structural heart type applications. We spoke about the magnetic approaches there at the start of the presentation, a lot of the cardiac mapping procedures and things like that are using robotic systems or magnetic systems to guide the catheter, but those catheters are generally down around less than 8 French size so much smaller catheters with much lower forces to steer so when you get into the higher forces … you're more mandated to use a mechanical steer system.

It seems both balloon-assisted and self-expanding valve implantation are common. From a delivery system side, would you design the catheter system differently based on the valve type? For example, would one need more column strength or tensile force than another?

O'Malley: I would always design a delivery system and consider the implant as it was. So, you have to do the two in tandem. So, if one is a balloon-expandable system then of course you're going to have to design it differently compared to something that is self-expanding. A balloon-expandable system won't have that radial force that I spoke about so maybe you'll get away with a much thinner wall or a much more forgiving system in terms of not having to retain this high radial force that would exist in a self-expanding stent, so I think you would design them very differently for sure.

What do you mean by downsizing? How small should these catheters be for mitral valves or other applications?

O'Malley: The way the aortic systems have gone, they've dropped 10 Frenches over the course of a number of years so this is a huge benefit to patients. At the incision site where you access the venous system or arterial system there's a smaller incision point made there so less complications for closing that. So, then ultimately if the device is smaller, it's imminently easier to track it through the body, so I expect mitral will be no different in that context. There will be a demand for smaller sizes.

When designing large-bore catheters how do you prevent kinking during deflection?

O'Malley: There are different types of reinforcements that you can use in the wall of the catheter to keep that inner lumen patent and prevent kinking. A good way of doing this is introducing a coil type design into the wall of the catheter and this gives you good crush resistance and good lumen patency then when you deflect the catheter there, so that's a good approach to do it.

Are variable durometer extruded materials used along the length of the catheter to augment the behavior of the catheter when executing a bend?

O'Malley: Something that you need to do to create kind of pivot points or points of inflection is use softer geometer materials at certain points along the length of the delivery system, and in fact it creates a kind of a hinge effect or deflection point at the soft points. So, then depending on what shape you want to make, then you can vary the length of these softer sections or just have multiple ... polymer along the delivery system to give you a particular shape in the distal area.

What number of deflection cycles do you design catheters to?

O'Malley: It's down to the user needs. So, generally we would test catheters to whatever the user input is and they're all very different in terms of their use, so it'll be tested to its user input specification.

Are there disadvantages of laser cut hypo tubes steerable sections compared to braided?

O'Malley: I would say that the braided gives a very efficient design in terms of your delivery system. The laser cut systems are machined components so they're very custom and bespoke, so they probably add to the cogs of your delivery system. And obviously then there's a supply chain issue that you have to deal with in terms of using those.

How would steerability or deflection relate to other areas of structural heart applications? Do you see all delivery systems moving to enhanced control and are there applications where steerability is not as necessary as others?

O'Malley: For sure, we know from radiology catheters back through the years that pre-shaped catheters are fine for these situations, but I think where catheter design is going in terms of remote control or robotic control systems that steerability is becoming more prevalent in lots of different areas. So, it's not there yet but you could see a situation where structural heart would enter the sphere eventually a number of years down the line maybe, but the general trend is that direction.

As the catheters get more complicated, are you seeing any pressure to make reusable devices?

O'Malley: Not so much. No, I think most devices now are single use and it's probably actually a move away from that more than anything else I'm seeing, so nearly the opposite direction.

What percentage of aortic volume does the catheter consume and what is the length of time this catheter is expected to be active within the heart or aorta?

O'Malley: All of these catheters are designed for short term use, so they’re specified for less than 24 hours. So, the length of the procedure, I’d estimate maybe an hour, maybe an hour and a half is generally how long the procedure lasts.

Is there an equivalent dimension in inches or millimeters for measurements in Frenches?

O'Malley: French size is usually 13.0131 inches, so you just multiply it by that number, by the French size.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)