News

thumbnail

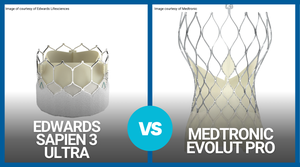

Cardiovascular

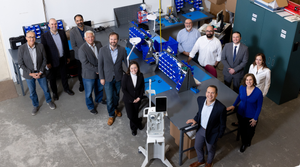

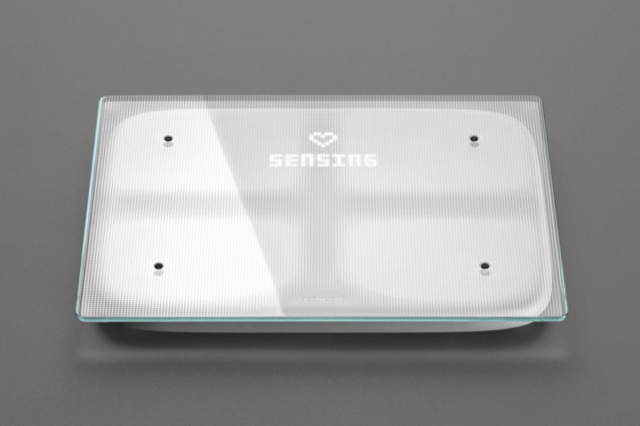

New Medical Devices & Partnerships Could Break Barriers & Lead to Better Heart Failure CareEmerging Medical Devices & Partnerships Could Power Better Heart Failure Care

New technologies like wireless patch electrocardiograms and cellular-connected scales aim to change remote heart failure care, potentially leading to earlier detection and more efficient management.

Sign up for the QMED & MD+DI Daily newsletter.