First Implants of 3D-Printed Synthetic Bone Graft Reported

Part of a new generation of biomaterials, CMFlex eliminates the need to surgically harvest material from the patient’s body to repair bones.

December 1, 2023

At a Glance

- The FDA-cleared, off-the-shelf bone graft material was developed by Chicago-based Dimension Inx

- Cleared by FDA in December 2022, CMFlex has been used in two patient jaw surgeries and several dental procedures

- CMFlex is composed primarily of hydroxyapatite and biodegradable polylactide-co-glycolide (PLG) polymer

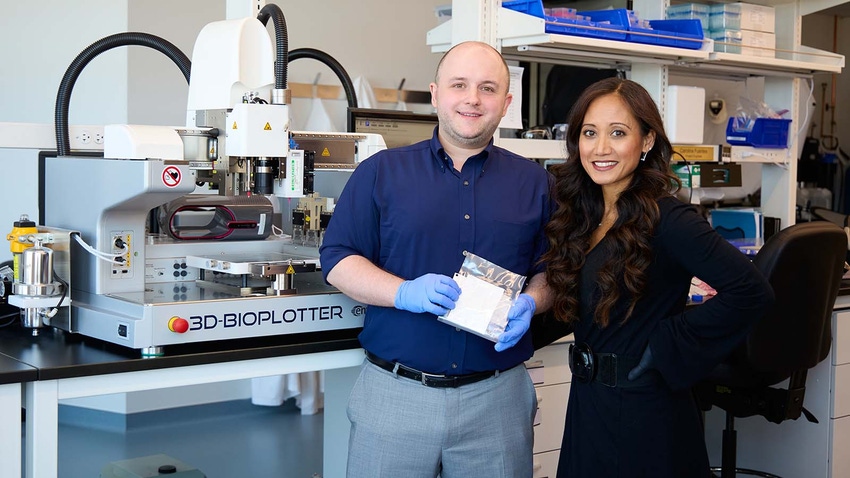

Desktop Health reported this week that CMFlex, a 3D-printed synthetic bone graft, has now been implanted in multiple patients. The FDA-cleared, off-the-shelf bone graft material was developed by Chicago-based Dimension Inx. It uses the 3D-Bioplotter from Desktop Health for the bioprinting applications.

Founded in 2017, Dimension Inx is a regenerative therapeutics company that designs, develops, and manufactures products to restore tissue and organ function. Its signature product, CMFlex, was cleared by FDA in December 2022 and has now been used in two patient jaw surgeries and several dental socket preservation cases. CMFlex eliminates the need for doctors to invasively harvest bone from a patient's body and shape it into a desired anatomy for a bone graft.

Dimension Inx developed and manufactures CMFlex on the Desktop Health 3D-Bioplotter Manufacturing Series model. The company owns four Desktop Health 3D-Bioplotters — two are used for R&D and the other two are used for manufacturing their commercial CMFlex product.

Biomaterial directs restorative cell behavior

"These first cases are not only indicative of a new generation of biomaterials, but also highlight our technology platform's unique capability to rapidly create biomaterials that direct cell behavior to restore tissue and organ function," said Chief Technology Officer and Dimension Inx co-founder Dr. Adam Jakus. "It is a proud moment for us to be able to demonstrate the value of therapeutics derived from integrating novel biomaterial design and 3D-printing approaches."

CMFlex is composed primarily of hydroxyapatite, a naturally occurring mineral found in bone, and biodegradable polylactide-co-glycolide (PLG) polymer. Dimension Inx combines them into a proprietary, microstructurally porous composite material, Hyperelastic Bone, first described in a paper published in Science Translational Medicine in 2016. The bone repair material is then 3D printed into CMFlex. which has an engineered architecture with nano, micro, and macro-level features designed to promote natural bone regrowth after implantation, without the need for an invasive autograft. Surgeons can size the product to match a patient’s anatomy and it is uniquely capable of absorbing fluid, according to the company. This property enables the material to control bleeding during surgery while assisting the bone remodeling process once implanted.

CMFlex is currently available to a limited number of key surgeons. A broader release will follow in 2024.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)