Capitalizing on 3D-Printing for Medical Device Manufacturing

BIOMEDevice Boston keynote speaker discusses innovation in eardrum repair using extrusion-based 3D-printing.

July 25, 2023

Easy problems are no fun, said Nicole Black, PhD, vice president of biomaterials and innovation at Desktop Health. Instead, she prefers tackling difficult problems because they produce innovative results. As her job title suggests, pursuing innovation lies at the heart of Black’s career goals, and at her upcoming keynote address at BIOMEDevice Boston, she plans to encourage attendees to take on their own difficult challenges to gain greater rewards.

“Keeping in mind the overall mission of what you're aiming to do and whom you're trying to help can really inspire and motivate you to get over those hurdles,” she said in a recent interview with MD+DI.

Black’s own experience has confirmed this. Her graduate work translated into a startup company that was then acquired by Desktop Metal, a public company. “Desktop Health was a brand-new division to Desktop Metal at the time when I joined, and the mission was to create better solutions for patients with these high-quality 3D-printing solutions,” she noted. “Our mission in our team is moving the nozzle in healthcare — trying to find applications where extrusion-based 3D-printing is valuable, not just for academic research, but also for end-use medical devices.”

Black’s latest project at Desktop Health is using the AlignInk biodegradable material system in the creation of the PhonoGraft device for eardrum repair. “We’re taking inspiration from nature and programming the way in which cells not only grow on grafts, but also in how cells eventually remodel these grafts into tissue that looks and acts like native tissue,” she said.

In her presentation, she will update the audience with the latest news on the company’s PhonoGraft device, as well as speak about the broader issues of 3D-printing in the medical device space.

Recently, MD+DI caught up with Black to ask her questions about some of the topics she’ll cover.

Can you give an overview of the AlignInk biodegradable material system and how it works with the PhonoGraft device?

Black: The AlignInk material system is intended for the manufacturing of 3D-printed tissue grafts where you have anisotropy inside of the graft. Anisotropy is a complicated word that simply means different material properties along different directions. There are many tissues in your body that look and behave differently in different directions. For example, blood vessels are lined with vascular endothelial cells that align with the direction of blood flow. In certain types of cartilage, there is an alignment of chondrocytes and collagen inside of that cartilage, such as in the fibrocartilage of the temporomandibular joint. Additionally, every muscle in your body has aligned myocytes that enable directional expansion and contraction.

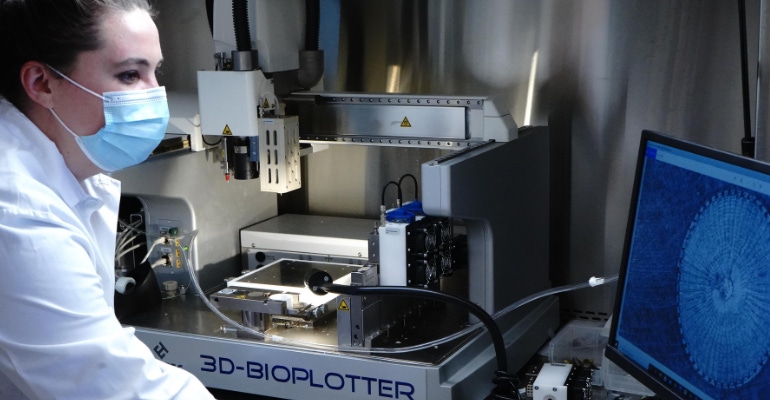

We designed the AlignInk material system to be able to guide the direction that cells grow on 3D-printed biomaterial grafts, ultimately to be able to reform these anisotropic tissues. It's essentially a way to guide cells and their deposition of extracellular matrix proteins, like collagen and elastin fibers, in different directions. We designed this ink system for use with extrusion-based 3D printers, such as the 3D-Bioplotter. There are several components inside of the ink system and during the extrusion process the ink system organizes itself in an anisotropic structure along the extrusion direction. By creating anisotropic grafts that can guide the direction of cell growth and extracellular matrix deposition, we're indirectly programming the structure of the final tissue.

For the PhonoGraft device, alignment is very important because your native eardrum contains circular and radial fibers that allow it to conduct sound well at both low and high frequencies. Most conventional tissue grafts used for eardrum repair are isotropic, which means their material properties are the same in all directions, or their anisotropic structure doesn’t match that of the eardrum. Thus, patients often have an entirely soft material replacing their eardrum or an entirely stiff material replacing their eardrum. Researchers have shown that radial stiffness in particular is very important for enabling hearing across a wide range of frequencies. So, if you just replace your eardrum with an isotropic tissue graft, you might be able to hear well at low frequencies but not high frequencies, or at high frequencies but not low frequencies, depending on the stiffness of the tissue graft.

This approach to 3D-printing is different from the approach taken by many medical device companies, wherein 3D printing is used primarily for customization, also known as patient-matching, of devices. While the macrostructure of devices can also be tuned using the AlignInk technology, we're also zooming into the microstructure of devices — to the level where cells interact with the device. At Desktop Health, we see 3D-printing not just as a means of prototyping and customization, but also as an end-use manufacturing method to impart unique structural and functional properties into devices for improved patient outcomes.

What recent achievements in material development have allowed the creation of this system?

Black: The material system that we’re working with contains a blend of biodegradable natural and synthetic polymers, which mimic the extracellular matrix surrounding cells in your body. The material system is hydrophilic to encourage cell ingrowth onto the grafts, and it’s porous to enable the graft to stick to native tissue around the defect site via capillary action. Sourcing medical-grade versions of these natural and synthetic polymers has been very important for us, and luckily, we are seeing an increasing number of materials companies providing their products in a medical-grade version.

Also, the extrusion technology itself, the 3D-Bioplotter, enables the AlignInk technology because you can apply relatively high pressures on to these ink systems that allow them to flow through nozzles with very small inner diameters. The 3D-Bioplotter has the largest range of accessible printing temperatures in the industry, from 2°C up to 500°C, so the rheological behavior of inks can be tuned through both material and temperature modifications. Ultimately, this leads to the production of high-resolution printed devices with high reproducibility between batches.

Why was eardrum repair chosen as the first project for Desktop Health?

Black: We chose the PhonoGraft device as our first major internally driven project because there is a very clear unmet patient need for improved eardrum repair grafts. I started tackling this problem while I was a graduate student in Professor Jennifer Lewis’s Lab in the Wyss Institute for Biologically Inspired Engineering at Harvard. Professor Lewis leads an incredible research lab focused on developing 3D-printing and materials technologies to tackle big problems in fields ranging from soft actuators to organs-on-a-chip. In early 2015, I met Dr. Aaron Remenschneider and Dr. Elliott Kozin at Massachusetts Eye and Ear Hospital, and I started learning about the challenges faced by patients who have undergone eardrum repair procedures. Seeing these procedures firsthand and listening to patients talk about their experiences motivated us to create grafts that could lead to improved outcomes.

During our early investigation into non-ideal hearing outcomes following eardrum repair procedures, we discovered work that related the eardrum’s unique structure to its ability to conduct sound waves across a wide range of frequencies. For example, Professor Sunil Puria’s group at Stanford University and Massachusetts Eye and Ear Hospital demonstrated the importance of anisotropic stiffness to sound conduction by designing a computational model of the middle ear with varying material properties across the eardrum. Another study from his group showed that cutting oriented slits in eardrum tissue led to differing effects on sound conduction depending on the direction that was cut. Despite these research findings, there were no existing products that even attempted to recreate the circular and radial architecture via a tissue graft. It was a great area in which to innovate.

Additionally, we realized that current eardrum repair procedures are invasive and cumbersome, with patients typically undergoing general anesthesia and spending an entire day at the hospital. Unfortunately, autologous tissue grafts that are harvested from a donor site, such as fascia or cartilage, require additional time and incisions into the patient. Additionally, it can be challenging to implant these grafts such that they cover the perforation on the medial side of the eardrum. We are designing the PhonoGraft device such that it will be possible to implant through the ear canal in an awake patient by any ear, nose, and throat (ENT) doctor trained in using an endoscope.

So, a major reason why we are excited by the PhonoGraft device is because it utilizes innovation from two different lenses to improve patient outcomes. The first lens is microstructural control with the AlignInk system. By patterning this ink system into a graft with a circular and radial structure, we can hopefully enable the body to remodel the graft into tissue that matches this structure, which could lead to improved healing and hearing outcomes. The second lens is macrostructural control with the 3D-Bioplotter and with our unique support materials that can be deposited alongside the AlignInk system. By designing the PhonoGraft device such that it can sandwich the perforation on both the medial and lateral sides of the eardrum, we aim to make the procedure more efficient and accessible to patients from all demographics.

What are the special regulatory challenges for bringing these types of devices to market?

Black: When most people think of regulatory challenges in 3D printing, they think of patient-matched devices, which are custom devices designed to fit the anatomy of a specific patient. When a company chooses to go down this pathway, devices can be manufactured in infinite array of designs that each need to be validated, which presents unique regulatory challenges. Fortunately, we’re not going down the patient-matching pathway with the PhonoGraft device, as eardrum repair devices do not need to exactly match the size of the eardrum perforation. Instead, we're developing a standard PhonoGraft device kit containing three sizes that should be able to treat most eardrum perforations. The PhonoGraft device provides an area of overlap between device and the residual eardrum tissue so that native cells can more easily migrate onto the graft from its circumference to close the perforation.

The FDA has confirmed eligibility of the PhonoGraft device for the 510(k) pathway, which is a premarket submission demonstrating that the device to be marketed is as safe and as effective as a legally marketed device. Since the grafts can be implanted through the ear canal, the FDA mentioned in our pre-submission meetings that they would like to see a small human confirmatory study to confirm that the device can be successfully placed in both operating room and office settings. I would say that this has been our most unexpected regulatory challenge, as human studies are rarely required for the 510(k) pathway. However, this is an indication that we're innovating on so many fronts. We are using novel material systems, a novel manufacturing method, and a novel design for improved implantation. Innovation is good, but it needs to be justified as safe and effective, especially for regulatory bodies such as the FDA.

How do you see this area of 3D-printing in the medical device space evolving?

Black: I've seen increasing interest in 3D-printing for the orthopedic space and for the vascular grafts space. In particular, the development of cylindrical grafts for vascular, respiratory, intestinal, and other channel-like tissues will be accelerated by the recently-released PrintRoll platform, which is a rolling substrate for the 3D-Bioplotter. The PrintRoll platform’s tightly controlled rotation speed coupled with spring-loaded, easily exchangeable mandrels of different sizes make it ideal for medical device development. I'm really excited to start working with medical device company partners to develop innovative new devices utilizing the 3D-Bioplotter, the PrintRoll platform, and our AlignInk material systems. Our team’s motto is “Moving the Nozzle in Healthcare,��” and I truly believe that we are moving the field forward daily.

I think that what we'll be seeing from the 3D-printing field at-large is an increase in companies using 3D-printing as a manufacturing tool to impart unique microstructural properties into devices that they cannot achieve through conventional manufacturing techniques, such as injection molding, milling, and turning. I hope that in the future, people don't just see 3D-printing as a method for prototyping or for creating patient-matched devices, but rather, I hope people fully utilize 3D-printing’s potential to impart specific material properties and functions into end-use parts and devices.

Who should attend your keynote address?

Black: This talk is relevant for anyone interested in medical device innovation, biomaterials, biofabrication, or 3D-printing. Part of the talk is going to be about how my graduate work translated into a startup company that was then acquired by a public company. So, I think that this talk will be particularly helpful for entrepreneurially-minded PhD students, postdoctoral research fellows, and folks in start-up companies. But also, if you're at a big company and you're interested in 3D-printing, one of my current hats at Desktop Health is partnering with companies to co-develop next-generation 3D-printed medical devices. Through the Desktop Health Biofabrication Innovation Office, based in Charlestown neighborhood of Boston, our team can set up joint development agreements to conduct early and late-stage R&D work. Many medical device companies are experts in specific market areas and have customer needs in mind, but they often do not have the 3D-printing or biomaterials development expertise to develop a brand-new device from the ground up. Therefore, I encourage folks in big companies that are interested in innovation to also attend.

I think it would be great to get some questions from folks about the different areas — including sourcing materials, formulating inks, designing devices, thinking about the regulatory pathway of a new device, and developing test methods for the final device.

What do you hope attendees take away from your keynote address?

Black: I hope that people take away that innovation is challenging, but it is worth it. Many medical device companies shy away from innovation for the reasons I mentioned earlier, including the FDA requiring more extensive testing to be conducted prior to device clearance. However, the markets that you'll ultimately unlock and the competitive advantages that you'll have are going to be so much more powerful than they would be if you had chosen a less innovative pathway. I really hope that people realize that if they're working toward a problem and it's very challenging — that is a good thing. Easy problems are no fun to solve.

Black will give the keynote address, Moving the Nozzle: 3D Printing for Medical Device Manufacturing, at BIOMEDevice Boston on Thursday, September 21, from 1-2 p.m., at Center Stage.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)